So we have a CNC router that has been steadily modified as required over the last few years.

Its a solid beasty with a steel beam and big steppers driving rack and pinion mechanisms, we use it a lot for 2.5D (sheet cutup/out) and a little for 3D (vac form plugs).

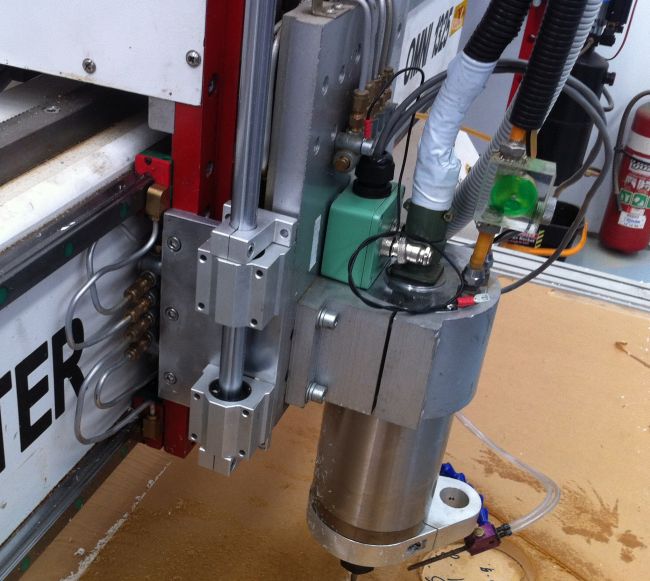

As of a few weeks back, it looked like this:

You can see that it has a bog standard vacuum shoe clamped to the spindle. OK, so we may have tweaked the dust extractor setup from stock......

Having a dust boot clamped to the spindle is bad if you are making deep cuts because you have to lift it up so it doesn't foul the material when you get down deep. This means that dust gets everywhere at the beginning of the job.

They are bad because air just gets pulled in through the brushes.

They are bad because the suction is applied at the front not near the tool.

They are bad because, when any part of the boot loses contact with the job, you lose suction.

etc.....

One day I was helping someone set up a Texcel router about the same size as ours but about 5 times as expensive. This thing had all the fruit, pop up stops, multi level tool height settings, stone bed, ATC , you name it.

One of the things it had was a vacuum foot who's height was set independently of the spindle... GENIUS!

So, when we smashed the old boot off the spindle whilst running a job with 100mm of cutter stickout. I decided to bite the bullet and build me a better boot...

First up was some cheap linear bearings mounted on to the fixed part of the head:

Then we cut the body from some 20mm acryllic:

Finally it all came together:

and

(apologies for the portrait mode)

Now I've put three sheets through the machine this afternoon and there is not 1 grain of dust to be seen anywhere. This thing is freaken AWESOME!!!

Better yet, one of the jobs involved cutting some thin strips from 6mm ply and the upcut tool started to lift the sheet off the vac table.

Normally this is either fatal for the job, or involves someone clambering around holding parts down by hand trying not to get hit by the machine...

All I did was release the clamp that was holding the new foot a few mm off the table and let it fall down under its own weight. The bottom edges are all chamfered, so it acted like a pressure foot and held everything in place....

So, three sheets and two beers later, we have decreed that a fixed height vacuum foot is a must have fix for any machine..

PK