Hello to all,

Hope everybody had a nice Christmas and Santa was very generous.

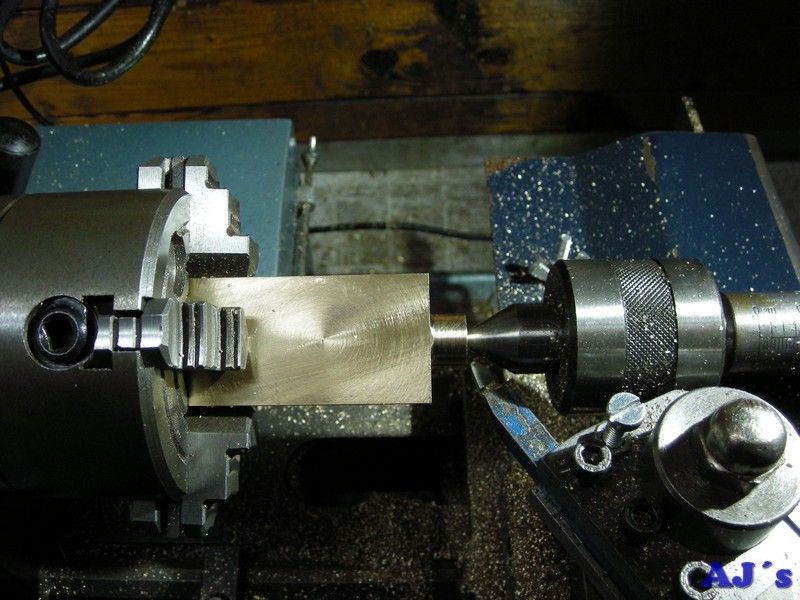

Next up was the valve chest and, as the mill is still out of commission, a piece of brass was fly cut to size.

Elmer's horizontal mill engine.

Elmer's horizontal mill engine.It was then centered lengthwise,

Elmer's horizontal mill engine.

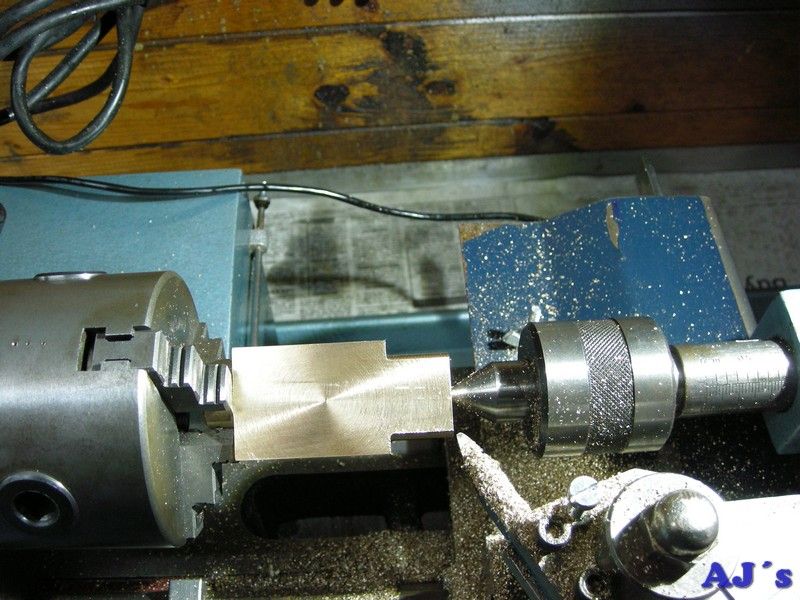

Elmer's horizontal mill engine.and the boss for the packing seal turned.

Elmer's horizontal mill engine.

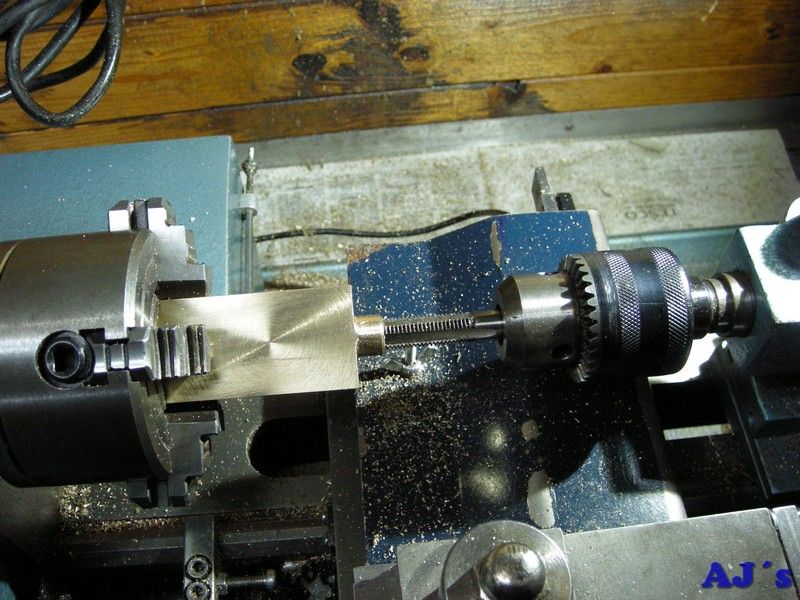

Elmer's horizontal mill engine.It was drilled and taped.

Elmer's horizontal mill engine.

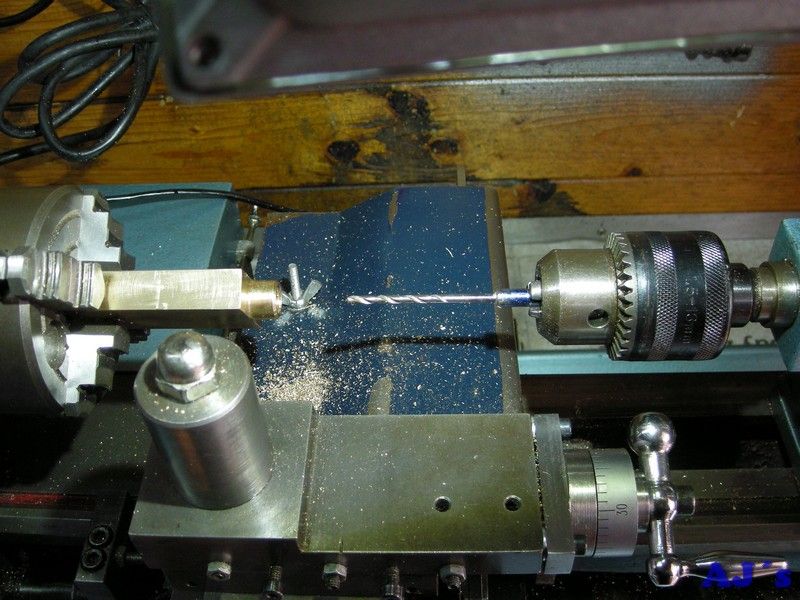

Elmer's horizontal mill engine.For the deep hole I had to make a long drill by soldering a drill bit into a length of bar.

Elmer's horizontal mill engine.

Elmer's horizontal mill engine. Elmer's horizontal mill engine.

Elmer's horizontal mill engine. Elmer's horizontal mill engine.

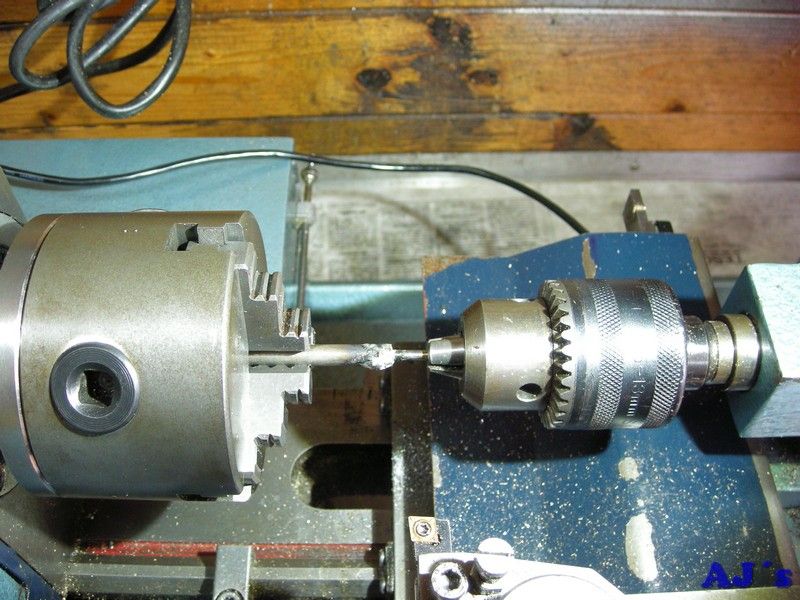

Elmer's horizontal mill engine.Test fitting the packing nut and valve pushrod.

Elmer's horizontal mill engine.

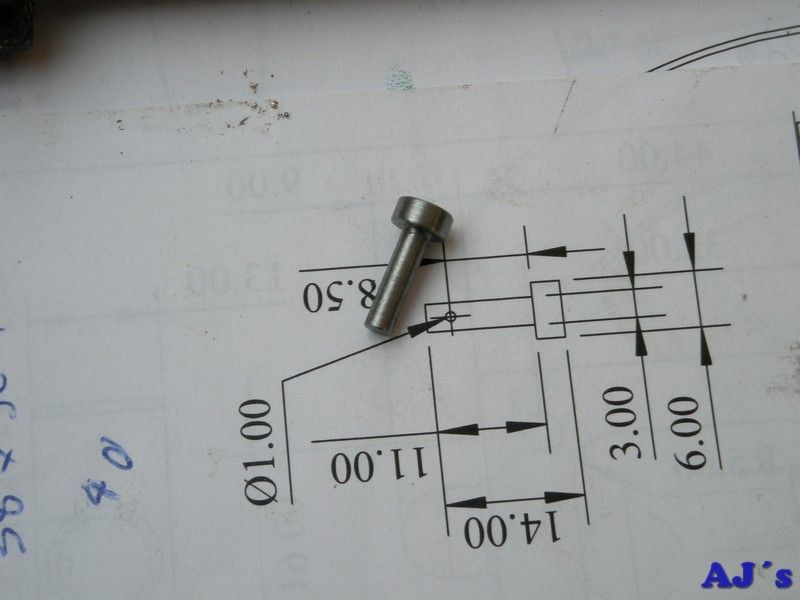

Elmer's horizontal mill engine.The part was then turned around and the boss on the blind side turned,

Elmer's horizontal mill engine.

Elmer's horizontal mill engine.and parted off.

Elmer's horizontal mill engine.

Elmer's horizontal mill engine.The round over was done by file.

Elmer's horizontal mill engine.

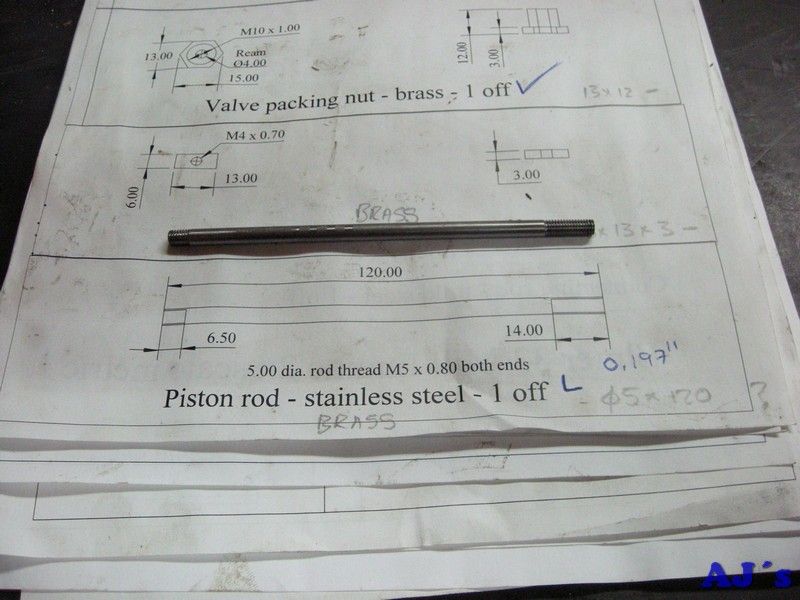

Elmer's horizontal mill engine.The piston pushrod was cut to length and threaded.

Elmer's horizontal mill engine.

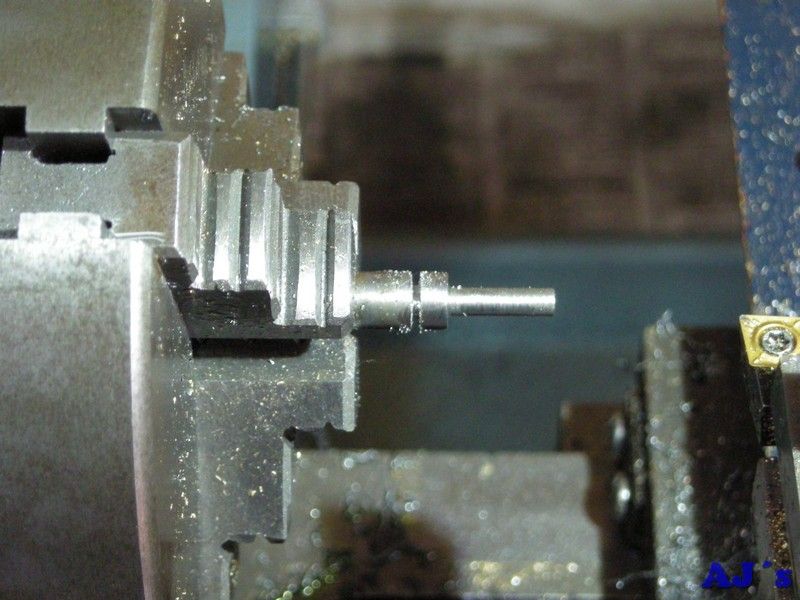

Elmer's horizontal mill engine.Tuning the pin for the valve pushrod.

Elmer's horizontal mill engine.

Elmer's horizontal mill engine. Elmer's horizontal mill engine.

Elmer's horizontal mill engine.Cheers

Abraham