A few months ago I decided that I've had enough of bare aluminum parts. I knew that anodizing wasn't that complicated, but the problem is that it's only used occasionally and when it's not being used, what the heck do you do with the stuff? So I devised an anodizing set-up that is ready at a moments notice (well, within the hour) and can be converted to a bench when not in use.

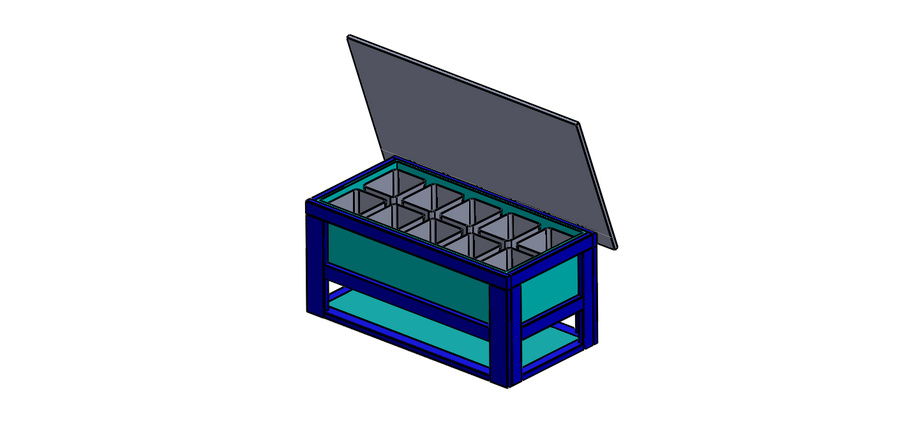

The key to getting the set-up compact enough is the use of rectangular 5.3 gallon buckets. At 10"x12"x15", they allow good capacity, but pack tightly so I was able to get ten of them inside the bench. That is enough to do clear and five different colors. They also have snap on lids that are hinged, so they can be closed up tightly when not in use. Once I had the buckets specked out, I proceeded to design a bench around it. The bench is basically a Melamine lined tub, with a shelf underneath for the power supply, controller and air supply, and a heavy duty hinged top with gas spring assist. The top is 34" off the floor, so it should make a good assembly area when not being used for anodizing.

Anodizing requires around 15VDC and up to 25A for a five gallon tank. I had an old DC supply on hand so that's what I used for power. I still had to build a controller to measure and control the temperatures of the various processes and that proved to be the biggest challenge of the project. I'm pretty good at machining and woodworking, but basically suck in electronics. I know just enough to get myself in trouble, but not really enough to get myself out. It did turn out pretty well, but not without issue and I think I actually learned some stuff solving the issues which is a good thing.

There are three different temperatures required in anodizing. The anodizing tank itself must be kept between 70ºF and 75ºF. Most of the time, room temp is close enough so I made provisions to control it, but haven't had to heat or cool it yet. The dye tanks operate at 140ºF, so they require a heating coil. I found some nice SS ones on ebay that are 2000W at 220VAC. The sealer tank operates at 170ºF. That's a bit marginal for the polyethylene tanks, but I reinforced the sides and it seems to be working well so far. I may eventually go to a SS tank instead.

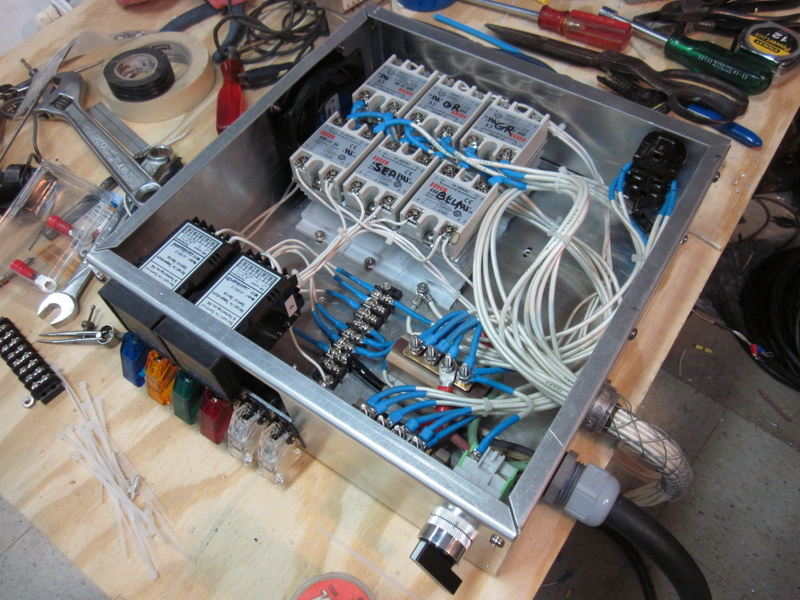

The immersion heaters are controlled by solid state relays which in turn are controlled bu a PID process controller and a thermocouple. The anodizing tank and the sealer tanks have their own controller, but I slaved the other tanks together to a single controller since they all operate at the same temperature. The concept is a bit "out there", but it seems to be working well.

The controller circuitry is enclosed in an aluminum box and includes all of the relays, process controllers, and dye tank selector switches (I only turn on the colors I'm using to keep from drawing too much current from the 2000W heaters). It also contains a fan and heat sinks for the relays, a power switch, a 110VAC outlet for the air pump and power supply and terminal blocks for the massive bundle of wiring.

Most of the processes require agitation so I made air manifolds out of CPVC that set in the bottom of the tanks and used a pond aeration pump to provide the bubbles. Each tank has a valve so I can balance the system or shut off tanks I'm not using.

The cleaner, dyes, desmutting solution, and sealer came from U.S.Specialty Color Corporation, the battery acid from NAPA, the caustic etch (lye) from an online place called Essential Depot and the distilled water and soda (battery acid neutralizer) came form Home Depot and Sam's Club.

When I want to anodize something it takes about 45 minutes to get the system heated up and stabilized. Then the process itself, cleaning, etching, desmutting if necessary, anodizing, dyeing if necessary and sealing takes about another hour and a half. So far, everything I've anodized has turned out flawless, so it must be a pretty simple process if I can handle it.

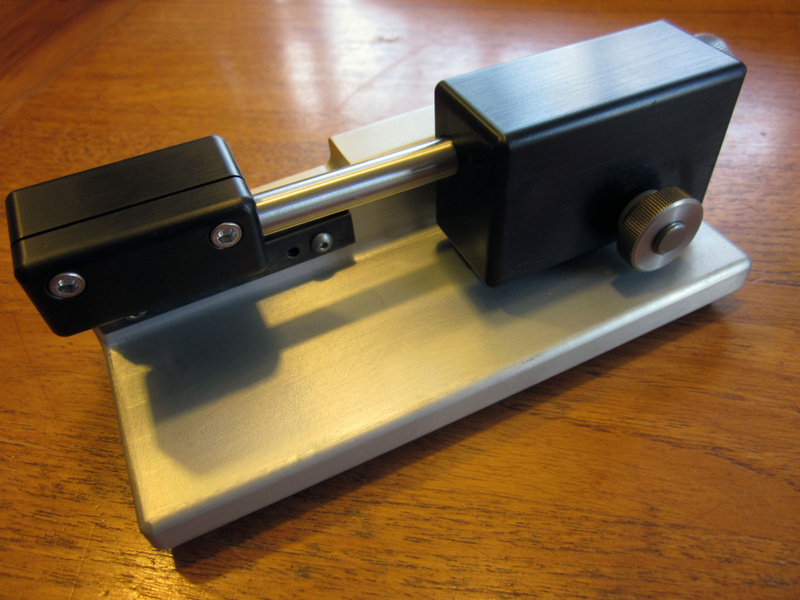

Here's a device that I built for work that I anodized clear and black.

So that's about it. The system probably could have been simpler, but then it wouldn't have been as much fun. About all that's left to do is make a removable trim panel to fill in between the tanks and build a cooling system for the anodizing tank for those hot summer day anodizing sessions. I also need to eliminate the SS hardware in the anodizing tank because the battery acid is consuming it and growing some amazing crystal. I think titanium or aluminum hardware will work much better.

Questions? Concerns? Laughter?

Tom