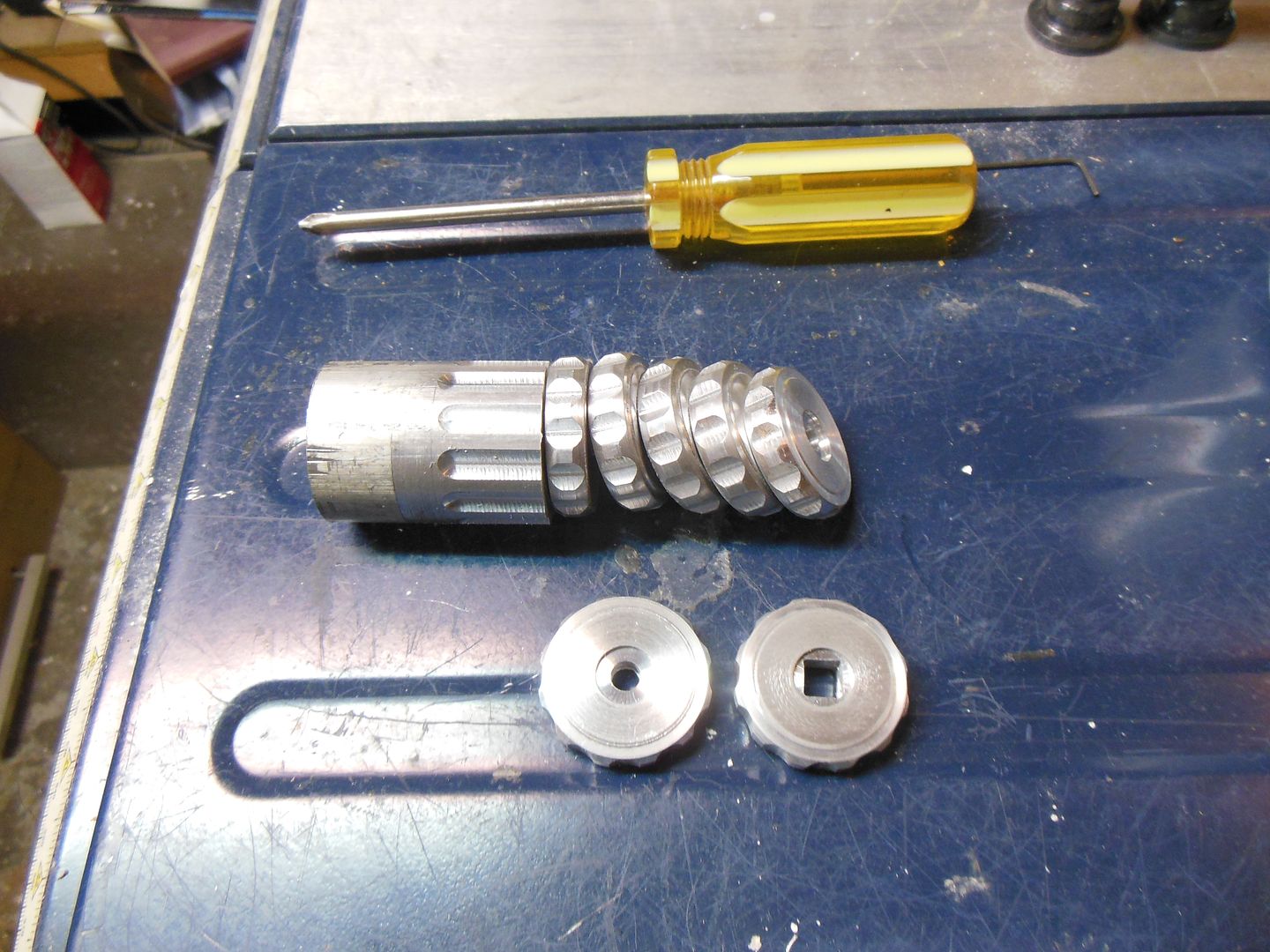

An longtime friend of mine can't shoot off-hand worth a damn. During one range session last fall he borrowed a bench rest from

somebody, and after trying it then decided that I needed to make him one, and what the heck, make one for me too. (Nice guy).

So,

and I got to work....

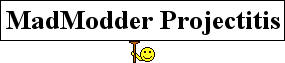

cut some lengths of allthread, turned, drilled, and tapped each end in the lathe, then milled a square section on one end for the knob

(horrible crap to turn, worse to tap!)

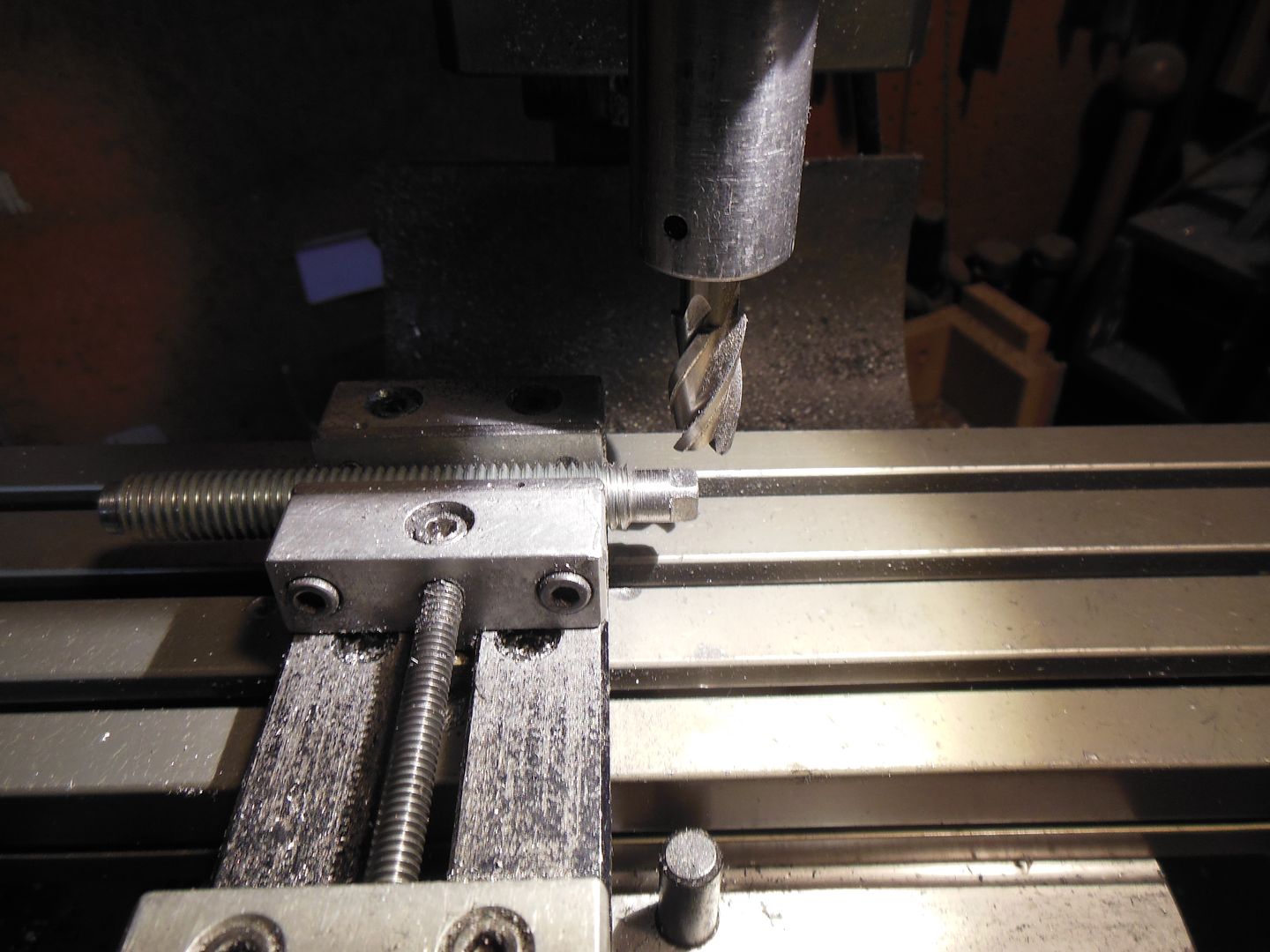

put a length of ali on the mill and cut flutes in it with a ball end cutter (and forgot to take a picture of the set-up) and then set it up in the lathe

and parted them off in turn, and milled the square with a 1/16" end mill

made up some "top-hat" shaped feet, these are held on with a washer and capscrew inside the "hat" , and then covered the bottom with some

peel and stick non-skid

the feet were turned, drilled & tapped, and here we are:

More to come....

Joe