Hi All , I have recently aquired a slotting head from Rob to fit to my Bridgeport mill, as per usual one job leads to another. Firstly the ram was solid when I tried to move it and I had to slide it to be able to swivel the head to fit the slotter, the slotting head was off a beaver mill and slightly different to the Brigeport mounting so a hole in the ram casting had to be enlarged.

After trying Wd40 etc , raw hide mallet, I resorted to the internet and found out the ram not sliding is quite a common problem and the best way around it seems to be clamping the ram forward with a sash clamp at each side and also trying to jack up the head slightly via wood blocks resting on the table and cranking the table to take the strain, well these did work but a right pain to do as the sash clamps want to pop off the curved surfaces of the ram and body and have to be turned one half turn each side and re set at the end of their screw thread travel, it would have been good to have been born with three hands for the job.

This is the sash clamp and wood arrangement, there was actually one clamp each side of the ram in the end to get it to move and the wood blocks were there to try and jack up to get releasing fluid to creep into the dovetails. I have at about half an hour to an hour per slide from back to front got it to move say 4 times and cleaned and oiled the dovetails as they stick out but its still only moving with the clamps, everything is loosened off etc , I am hoping the slotting head might balance out the weight from one end of the ram to the other and make it move better .

This photo shows what needed to be done to make the slotter fit , the Bridgeport ram hole is smaller than the one in the Beaver mill bracket that is resting on top in the photo, making the hole bigger meant the slotter could use the original pin and collars , nuts etc.

I turned up this tool , it fits through the original Beaver bracket as it is in this photo ( Beaver have a separate bolt on part where the Bridgeport has cast eye in the ram ) the tool at the lower end has the right size end to sit in the hole that is in the bridgeport ram and the top is turned to fit into a drill chuck, the bottom end has a tool steel cutter fitted to it.

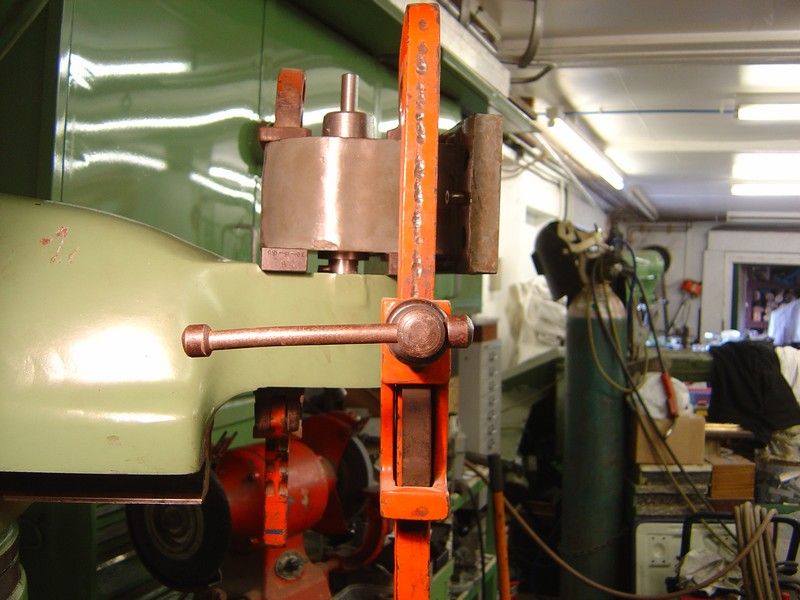

The bracket is then clamped with the tool in place this keeps the two holes in line and ensures the tool runs in the old bracket and widens the hole that is too small, well thats the therory anyway, I tried it and it was hardly cutting , Rob ended up kindly coming over to help me he reground the cutter and it was doing the job but still a pain and was flattening battery drills at some rate and wanting to burn out mains powered drill after a good while slowly keeping at it and keep charging battries it was getting there.

This is the set up with the drill in place.

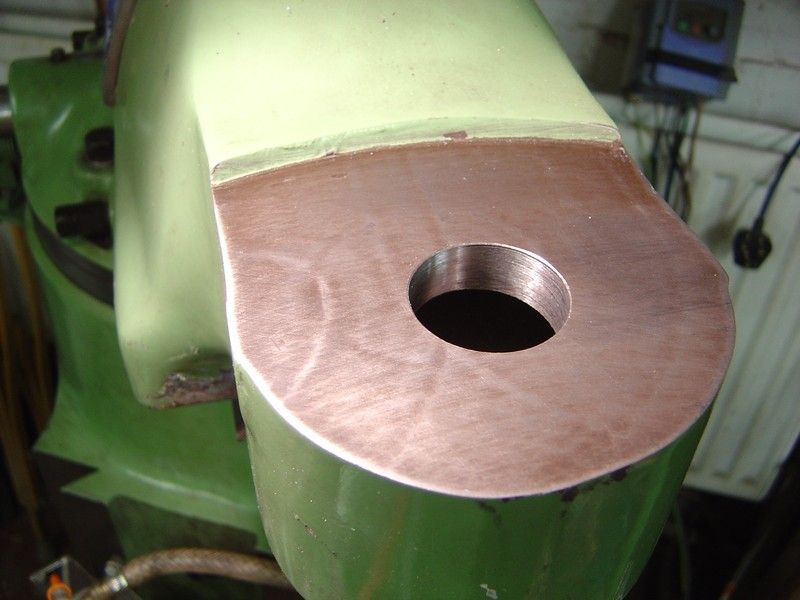

The finished hole, after a clean up with a flap wheel so the pin was a nice fit.

The bracket in position , it locks up as it should and is ready for the slotting head to be fitted, this has lead to the fact that the mill will need to be moved further out from the wall as there is not enough room to swing the head with the slotter fitted lol, another job to the list , I am going to make a jackable castor stand for the mill so its moveable in future.

Rob deserves a big thanks for helping me get the bracket fitted , I had been at it all day and would have cracked up trying to get it sorted on my own so Cheers Rob I owe you one mate.

Cheers Mick.