First of all, let me apologise to anyone who may have been offended, especially Woodsman22. It was never my intention, and I suspect I maybe suffering from Grumpy Old Git Syndrome. I think perhaps my way with words is not what it once was, so please let me communicate in a manner I am more familiar with.

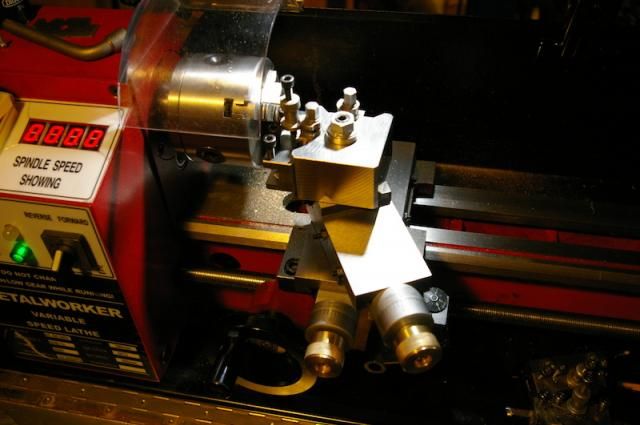

This is my mini lathe, mostly standard but it does haver taper roller bearings fitted. I for now just use the plastic gear set as they have proved more than adequate for my uses.

I have it set for the smallest thread pitch the mini lathe can cut (0.4mm)

The cross slide is set over at 29 degrees, just under half the 60 degrees of the finished thread. You can see that I swapped over the standard hand wheels for brass knurled, this was because I got fed up with the clashing wheels and also the time I caught the cross slide wheel, didn't realise and added to my cut so much it ruined the part I was making.

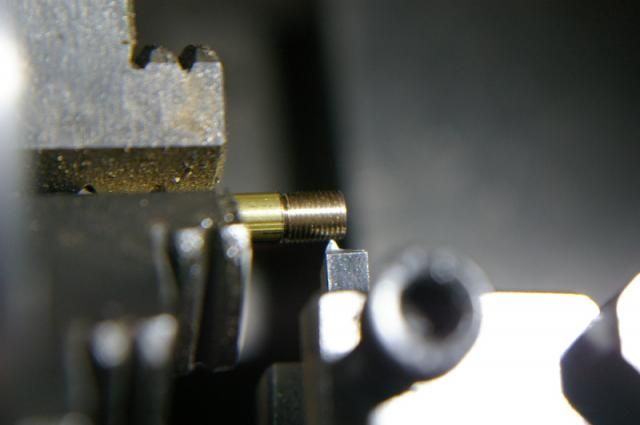

This is the thread I cut and you can see the lathe tool I made. It was a small parting tool I had made and broke the tip off, so reworked it into a thread cutting tool.

I don't have a tool and cutter grinder, so all my tools are hand ground on a bench grinder for larger tools or to remove bulk and then finished with diamond stones to get a good finish. The lathe tool was very roughly made and doesn't have all the angles they say you need, but I find generally I get good thread engagement and its good enough for me.

Finally a check of my finished thread against my thread gauge. The overall thread I made was 0.2mm undersized as on my second pass I engaged the thread dial on the wrong number, as others have mentioned doing

... But it doesn't matter as this was just a practice part, and proved I still need more practice cutting threads and that its better to back out the tool, reverse the lathe then re apply the cut without disengaging the leadscrew nuts in my case.

The point I was trying to make from the very beginning is that the lathe is capable of accurate work as is, and it is a good tool to learn on due to its low cost. The mini lathes do seem to come in for flak from people far more skilled than I. However the best way to get to grips with it is just to do it, in some cases over, and over again till you get it right. I will now decide what I am going to do with this item and make something else to go with it.

Hope this is of interest to you Woodsman22.

Regards

Joules