New member here and thought I would post up my current project.

A ball turner for my South Bend 10K

Purchased the Tapered Roller Bearing from local Advanced Auto Parts.

Driveworks S-A-4 seemed about the right size.

Purchased a 3" diameter x 3" long piece of 1018 steel. Dimensioned the plug or spigot end to fit the South Bend 10K. I had a set of HSS

bits made for dovetails using my Logan shaper so I used one to cut the plug end dovetail. Worked perfectly. Checked the fit with the chuck still attached to just reach that snug fit.

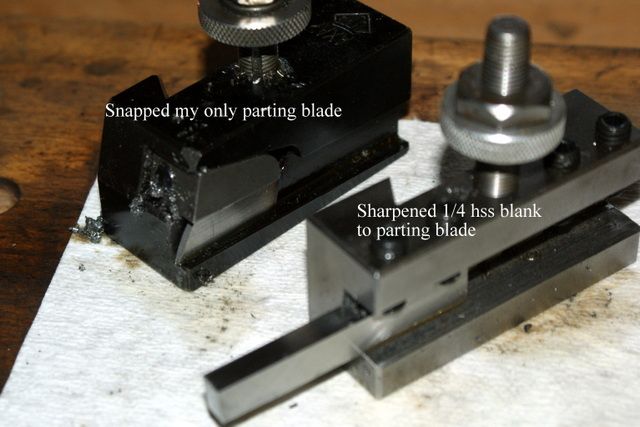

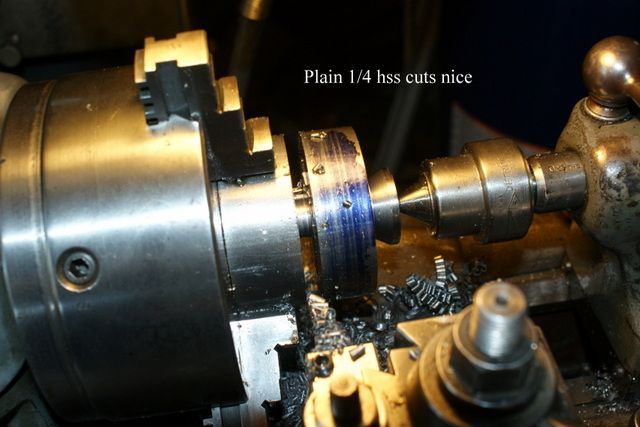

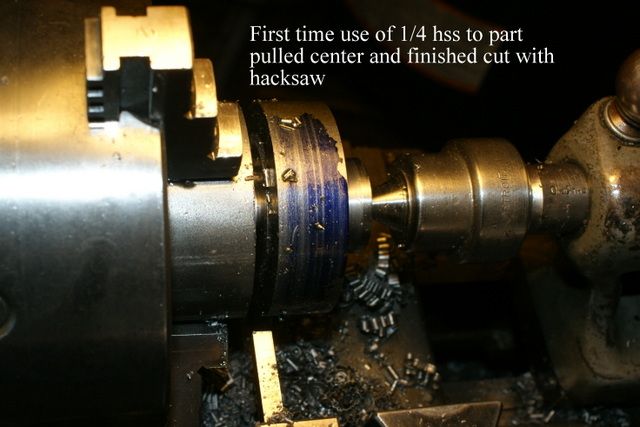

A slight cleanup cut of the diameter and I was ready to part the piece. OOPS....snapped my only cut off blade when I just started the cut. Stupid mistake and no injuries. I used a 1/4 HSS tool bit and ground about 5 degrees on the front. I just touched the sides a bit for relief and final sharpened all the faces by hand on a ceramic stone. Set it in an AXA holder, placed just low of center and gave it a try. Backgear was engaged and adjusted speed via my VFD. Surprised that it cut so smoothly and cleanly with the ribbons just pealing

out. Did not step it in at all, feeding it in until about 1/2 to 3/4 was left to pull the center and hacksaw off.

Faced off the piece and used another shaper tool to rough out the center for the bearing race. Picture of the tool below along with my dovetail bits. Nice when you have a shaper the tooling can be used on the lathe so easily. I just plunged in the diamond shaped tool for a cut then engage the crossfeed to cut to center. A short boring bar trued up the outer shoulder to fit the bearing race. Not shown but I did drill 3 1/8" holes through the body to tap out and remove the bearing race as needed. Also their is a slight recess inside the radius of the bearing race to clearance the bearing cage. The race is light tap fit and I did remove it quite a few time as I fit the bearing and designed on the fly as I progressed.

Next up I am up to my Logan shaper to machine the 1/2" tool slot and face the round so I can drill for the set screws.

Comments Always Welcome