Hi It's Me,

Thanks for the complement!

Hi everybody,

well, life has been getting in the way, so it's taken a bit of time to get back to you.

The remaining parts are the layshafts and the keyed bushes that carry two gears, locking them together. I've made these in to fit the Emco banjo, so that the two other sets of gears that I have will work there as well. This means that I have amongst other things, the 127 tooth gear for inch threads that I can now use.

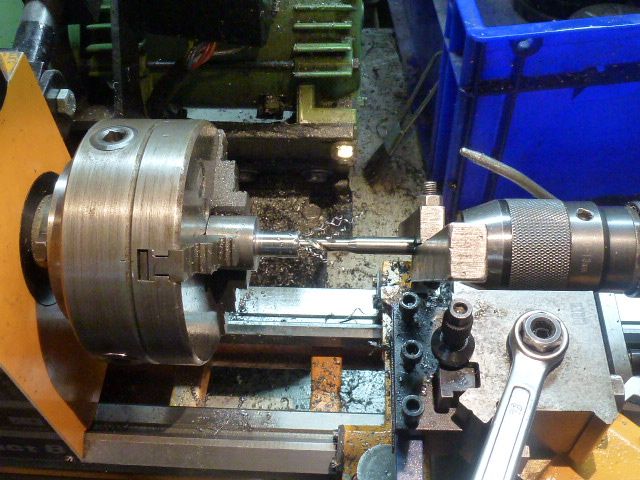

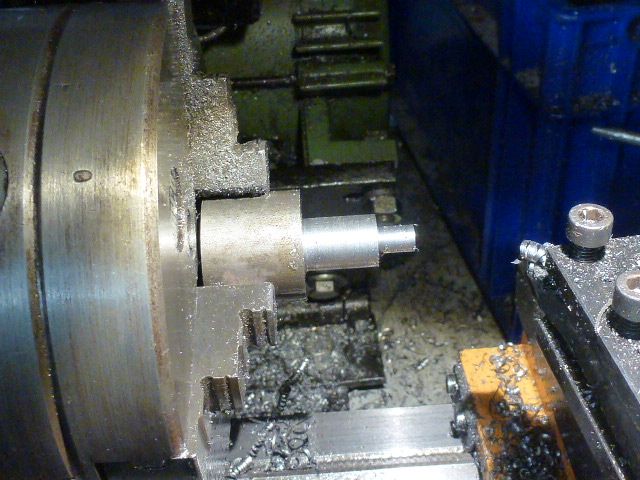

I needed two lay-shafts to mount the change gears on the banjo. A piece of cold rolled was reduced to 12mm in diameter a little shorter than the thickness of the banjo.

Drilled 6.75, to tap M8.

Tapped M8

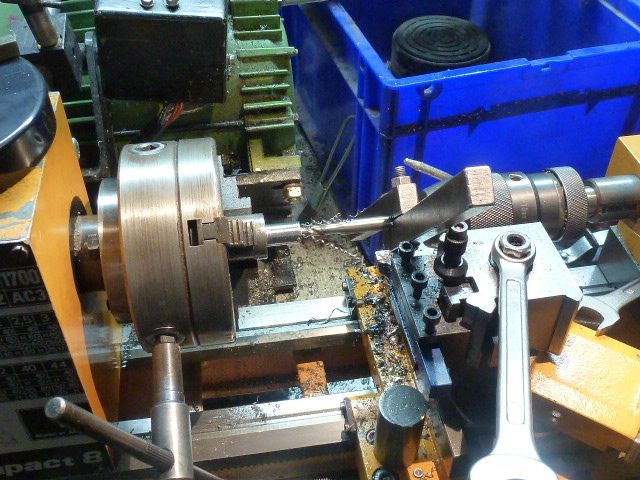

Test fit on the banjo.

I reduced the outside diameter to make it look nicer!

I drilled the gear side 5mm, tapping size for M6.

tapped M6.

Completed and in position. The large gear is mounted on the other lay-shaft using the sindle and keyed bush from the Emco.

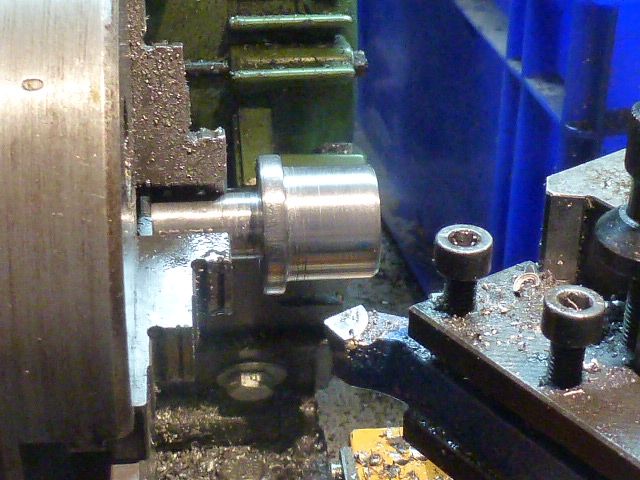

A piece of cold rolled, reduced to 6mm to thread M6.

Reduced to 10mm over 16.5mm, two gear thickness’s, with a little clearance.

Threaded to M6

Test fit.

Rather than thread and add a nut, I decided to make a built in button.

The button.

Test fit.

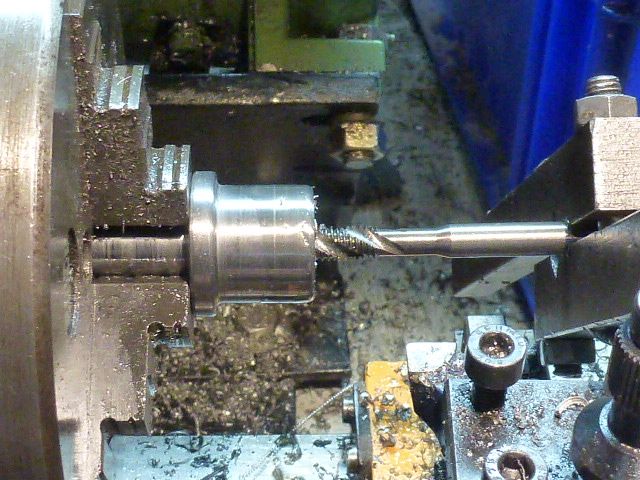

In order to couple two change gears together on a lay spindle, I needed to make keyed bushes. The key needs to be brazed onto the bushes, especially the 12mm ones as the bus is only 1mm wall. In the chuck I have a piece of cold rolled, turned to 14 and 12mm Øs this is going to make two 14mm bushes and two 12/14 stepped bushes.

Test 12mm plastic gear.

Test 14mm gear.

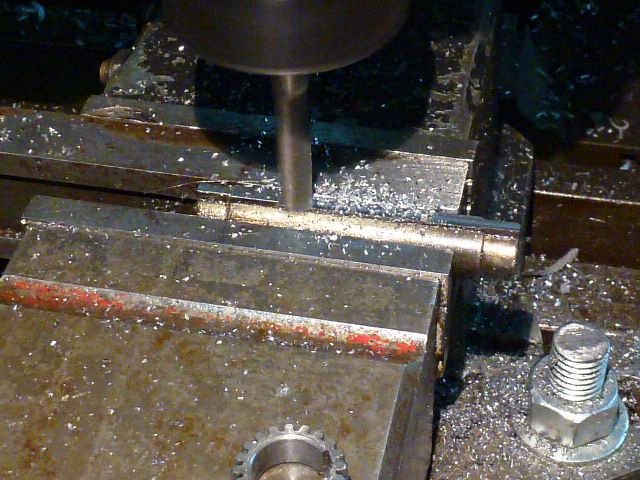

Milling the key way.

Key ways cut, one of the complications is that the 14mm gears have 4mm wide keys, whereas the 12 and 16mm ones have 3mm wide ones.

Key brazed in place.

Milling the key down to fit.

Test fit 12mm and 14mm.

2 14mm and 2 stepped bushes before drilling out to 10mm.

Finished 12/14mm bush.

Test 12/14mm bush.

The complete full set of bushes.

In the end, I decided to make buttons for all of the shaft ends, I only need one Allen key to make any combination of gear changes.

I learnt a lot on this project, my surface finish on the lathe has greatly improved. I found milling the 3 and 4mm key ways with a 2mm mill a little hairy to say the least but the mill was very docile and precise!

I'm really glad to have finished this !

Regards, Matthew