Hi all mad modders.

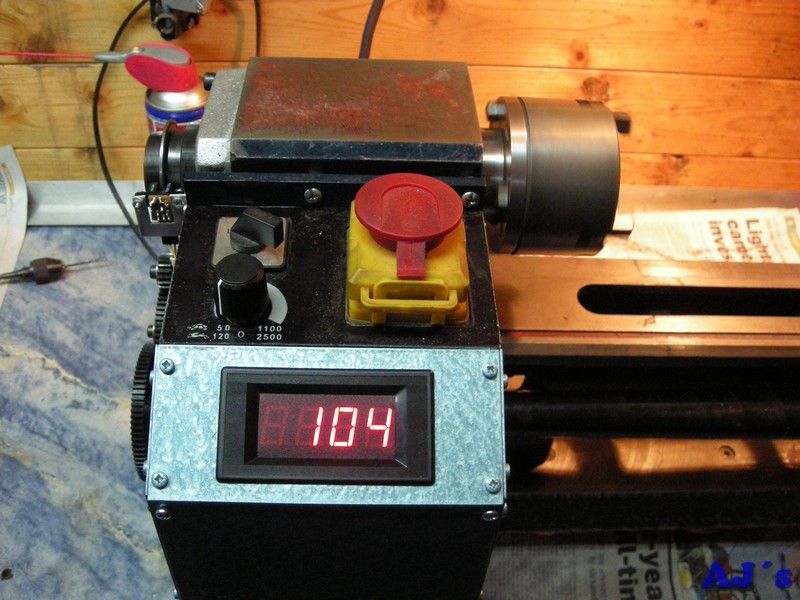

I wanted to add a tachometer to my 7x12 lathe. After a bit of research I ordered a digital panel mount frequency meter of the bay.

As frequency is pulses per second I had to make a plan to get 60 pulses for every turn of the spindle so the meter will directly read RPM.

Decided to make a counter wheel with 60 holes mounted between the nuts on the spindle.

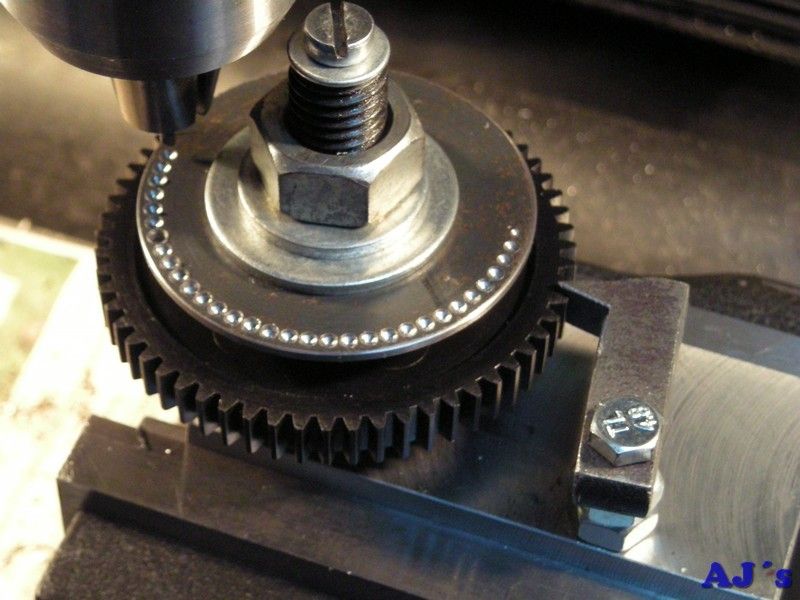

Made a quick indexer using one of the lathes change gears.

And used it to drill 60 1.2mm holes in a steel disc.

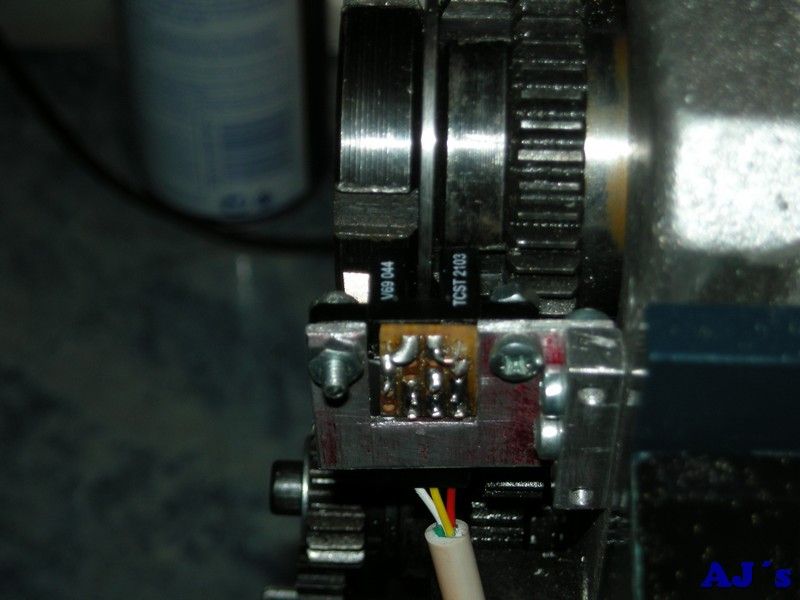

This was mounted on the spindle and an optical sensor was mounted on a bracket to the headstock.

I built a extension box that fit to the front of the lathe controls to house the meter and a supply that was salvaged from a mobile phone charger.

The meter works great and was tested with reference to a handheld tacho and reads within 1 or 2 RPM.

Cheers.

Abraham