Hi all,

Needed a boring head and decided to make my own as explained in "Milling a complete course" by Harrold Hall.

Pretty much followed the instructions and sequence in the book.

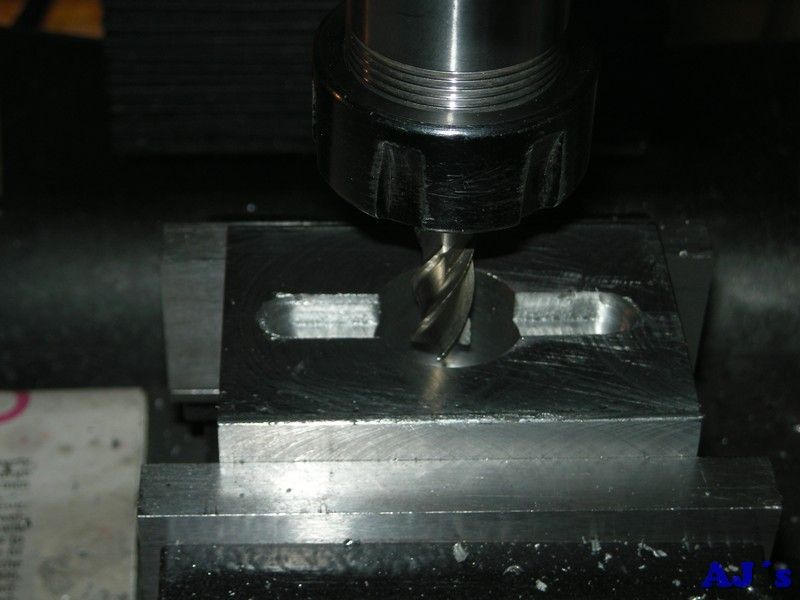

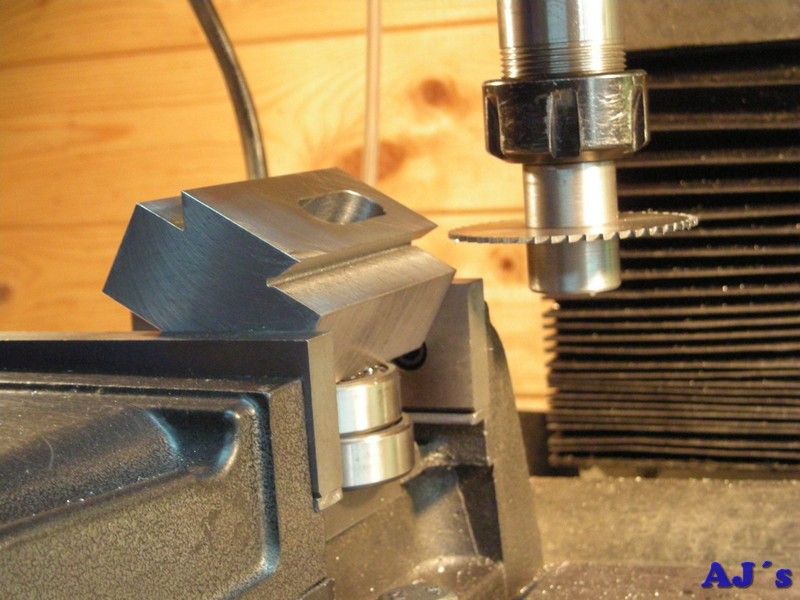

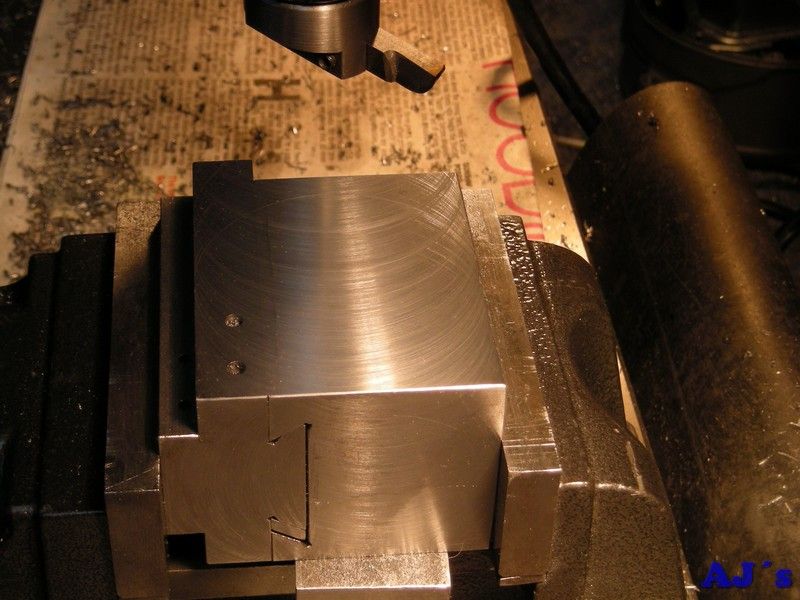

Fly cutting the contact surface after cutting the dovetail in the body.

Making a boring head.

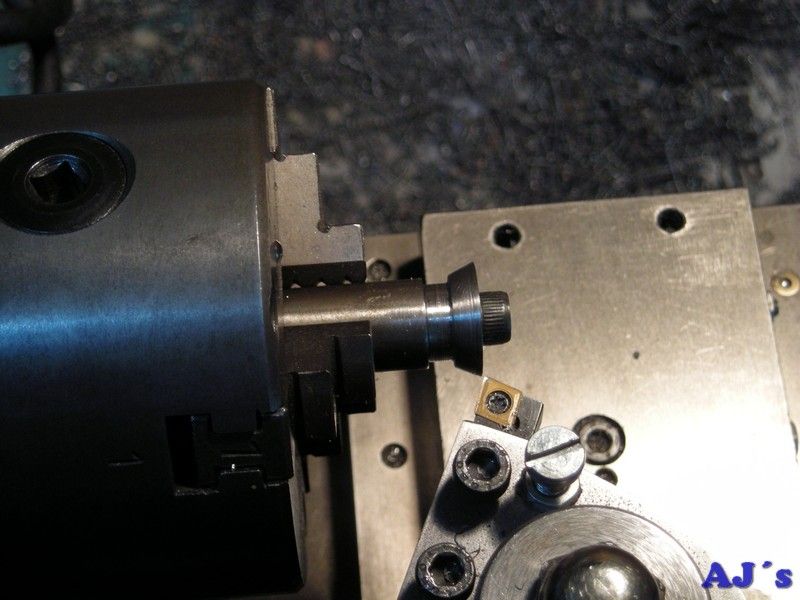

Making a boring head.Cutting the slots for the arbor.

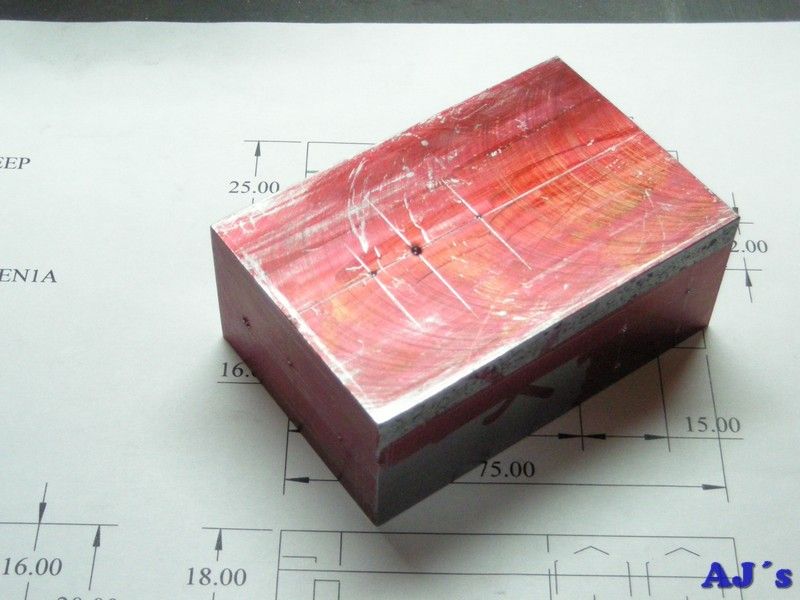

Making a boring head.

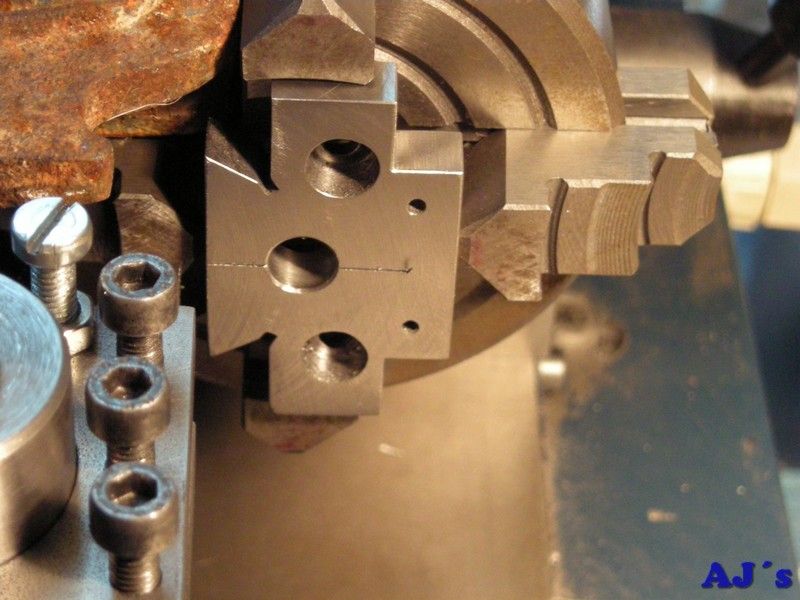

Making a boring head.Marking out and drilling holes in the cutter carrier.

Making a boring head.

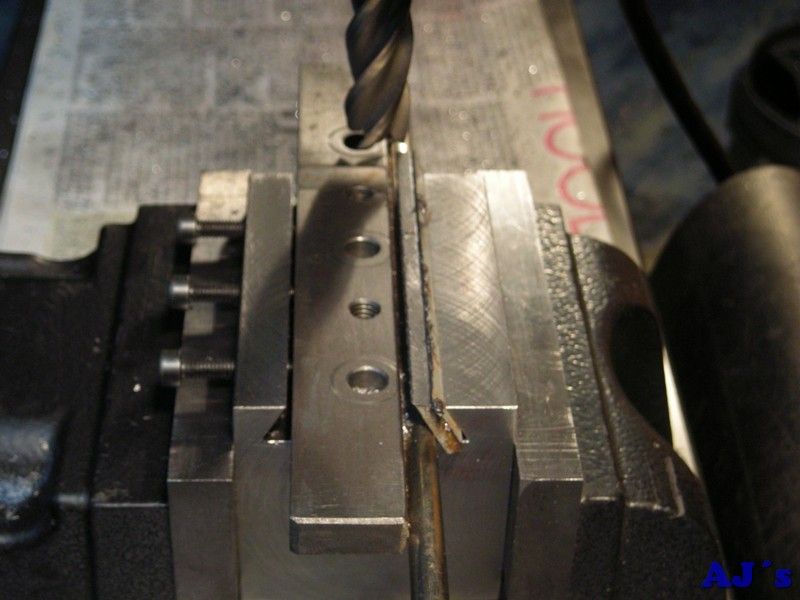

Making a boring head. Making a boring head.

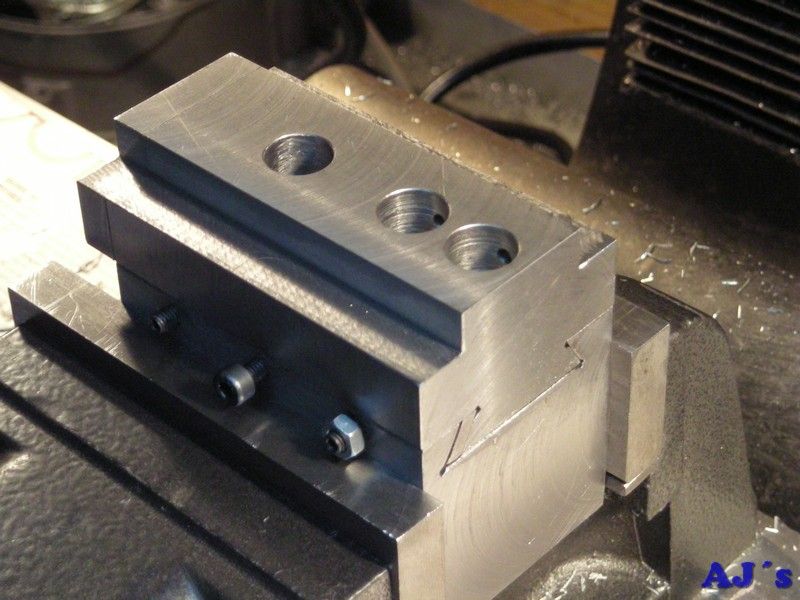

Making a boring head.Drilling holes in the bearing plate.

Making a boring head.

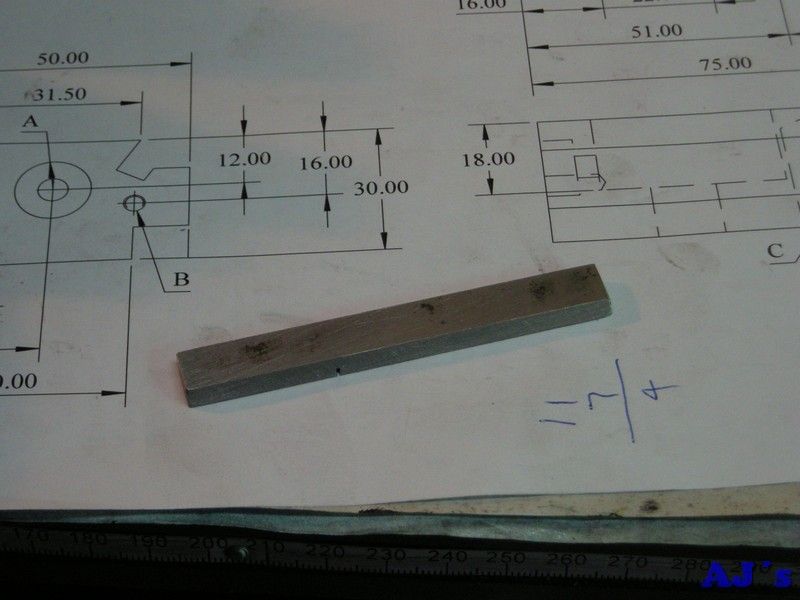

Making a boring head.Machining the gib strip.

Making a boring head.

Making a boring head. Making a boring head.

Making a boring head.Undercutting the dovetails.

Making a boring head.

Making a boring head.Making the lead screw.

Making a boring head.

Making a boring head. Making a boring head.

Making a boring head. Making a boring head.

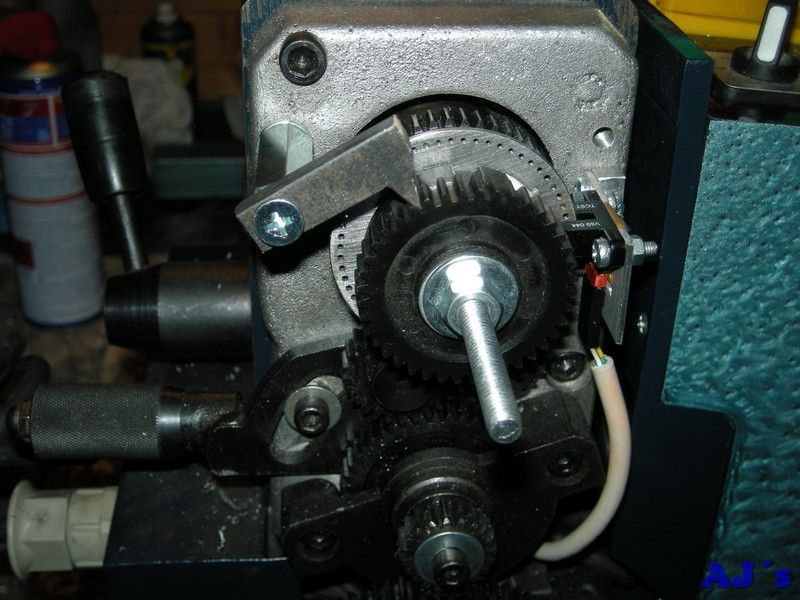

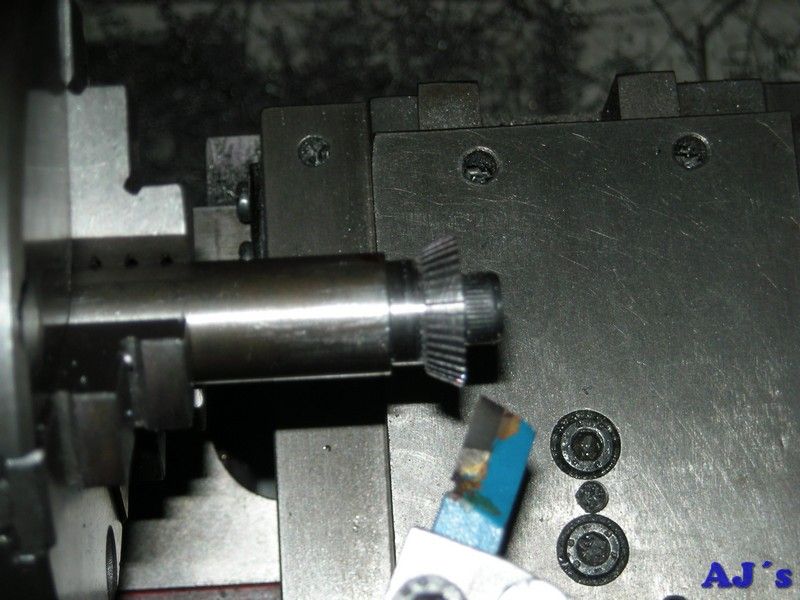

Making a boring head.Machining the dial.

Making a boring head.

Making a boring head. Making a boring head.

Making a boring head. Making a boring head.

Making a boring head.A makeshift indexer was used to do the graduations on the dial.

Making a boring head.

Making a boring head. Making a boring head.

Making a boring head. Making a boring head.

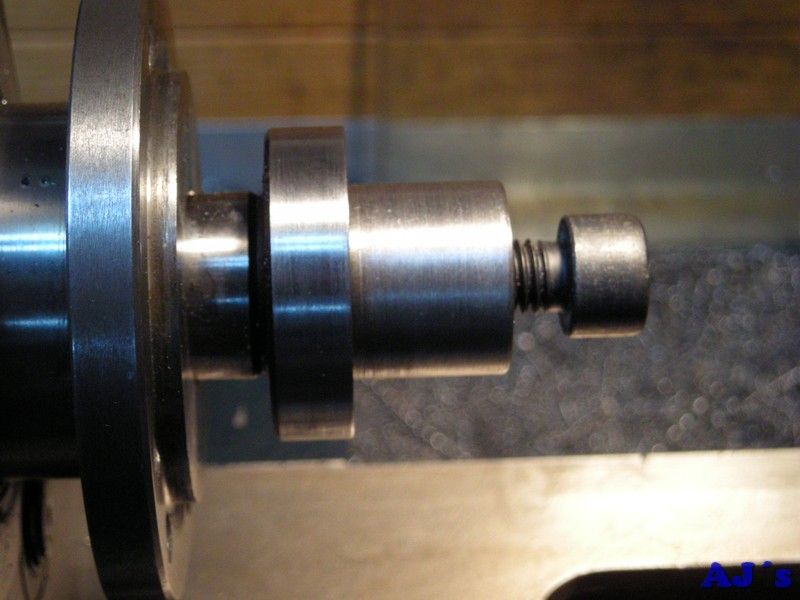

Making a boring head.Lead screw and dial together.

Making a boring head.

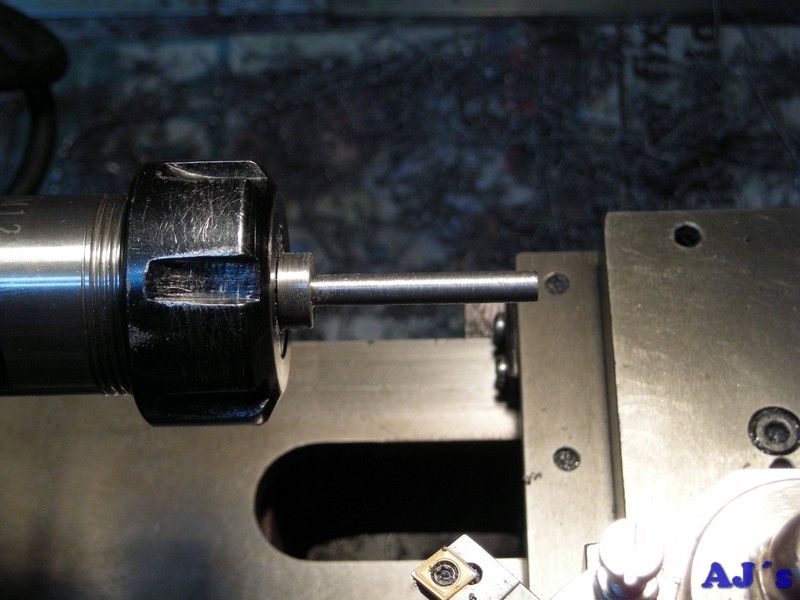

Making a boring head.Machining a MT3 soft arbor to fit the body.

Making a boring head.

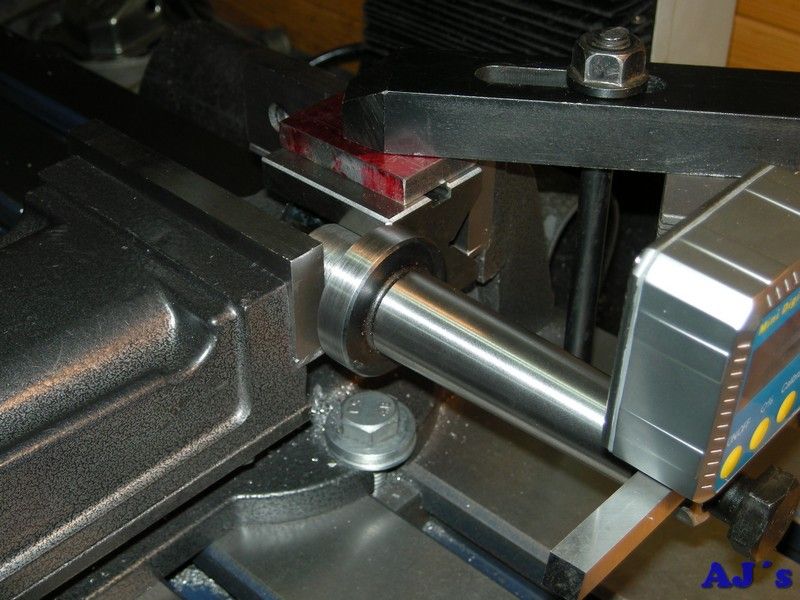

Making a boring head.Setting up to machine the slots in the arbor.

Making a boring head.

Making a boring head. Making a boring head.

Making a boring head. Making a boring head.

Making a boring head.The finished arbor.

Making a boring head.

Making a boring head.Removing excess from the cutter carrier.

Making a boring head.

Making a boring head.Fly cutting the sides together.

Making a boring head.

Making a boring head.Putting a reference mark on the bearing plate.

Making a boring head.

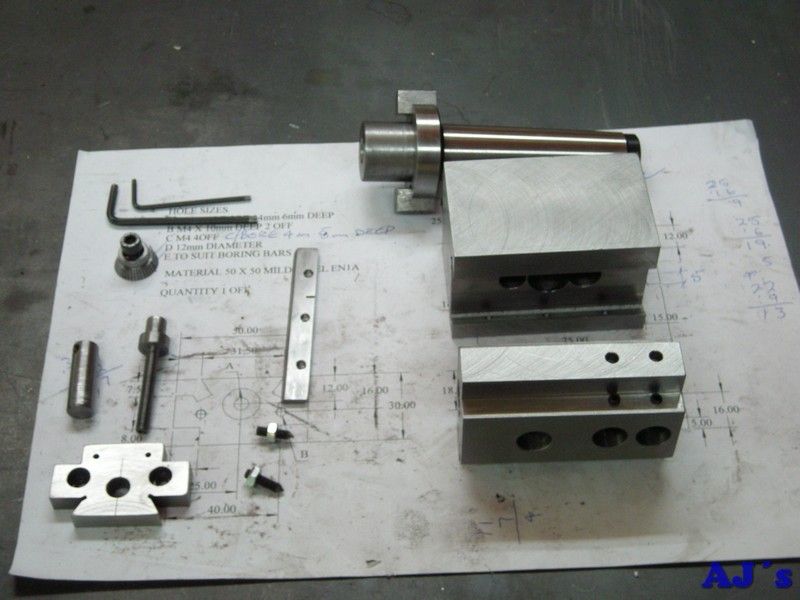

Making a boring head.All the components before assembly.

Making a boring head.

Making a boring head.The finished product.

Making a boring head.

Making a boring head. Making a boring head.

Making a boring head.Joined by two other little tools recently made.

Making a boring head.

Making a boring head.And fitted on the mill.

Making a boring head.

Making a boring head.This was a nice project to learn more advanced skills and I am very happy with the outcome. Had the opportunity to use the boring head on another project and it works perfectly.

Cheers to all.

Abraham