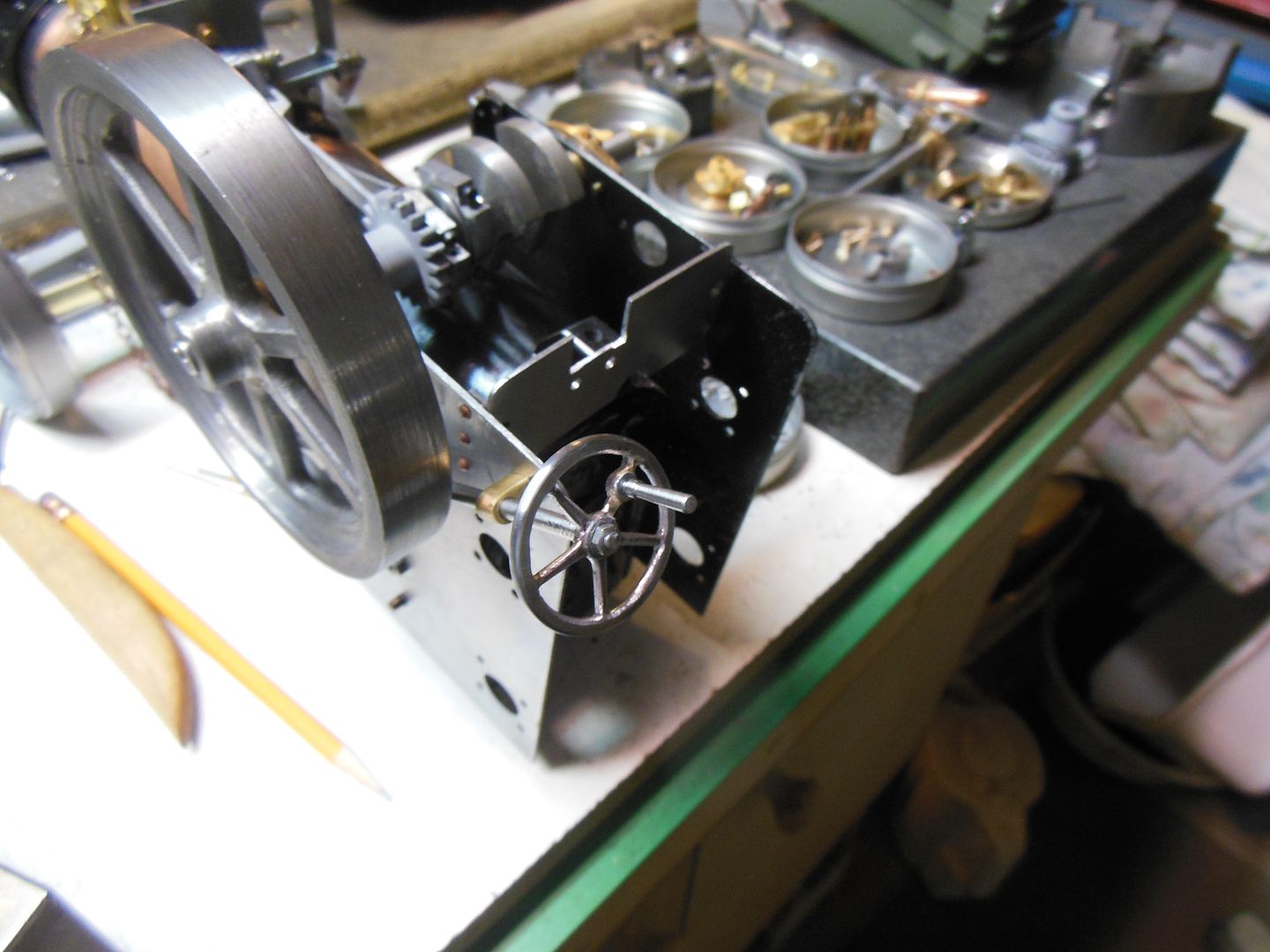

Finishing off the steering business, need a steering wheel...

Some faceplate turning:

off the faceplate, cut out the bits that don't look like spokes, soldered in a small piece of round stock

to act as the boss for a handle

Hacksawed off the greater part of the excess on the outside of the rim, mounted the wheel on a little stub of rod threaded to

fit, into a collet on the taig lathe and a lot of very small cuts to true it up

a quick little bit of turning and threading for the handle, and here it is

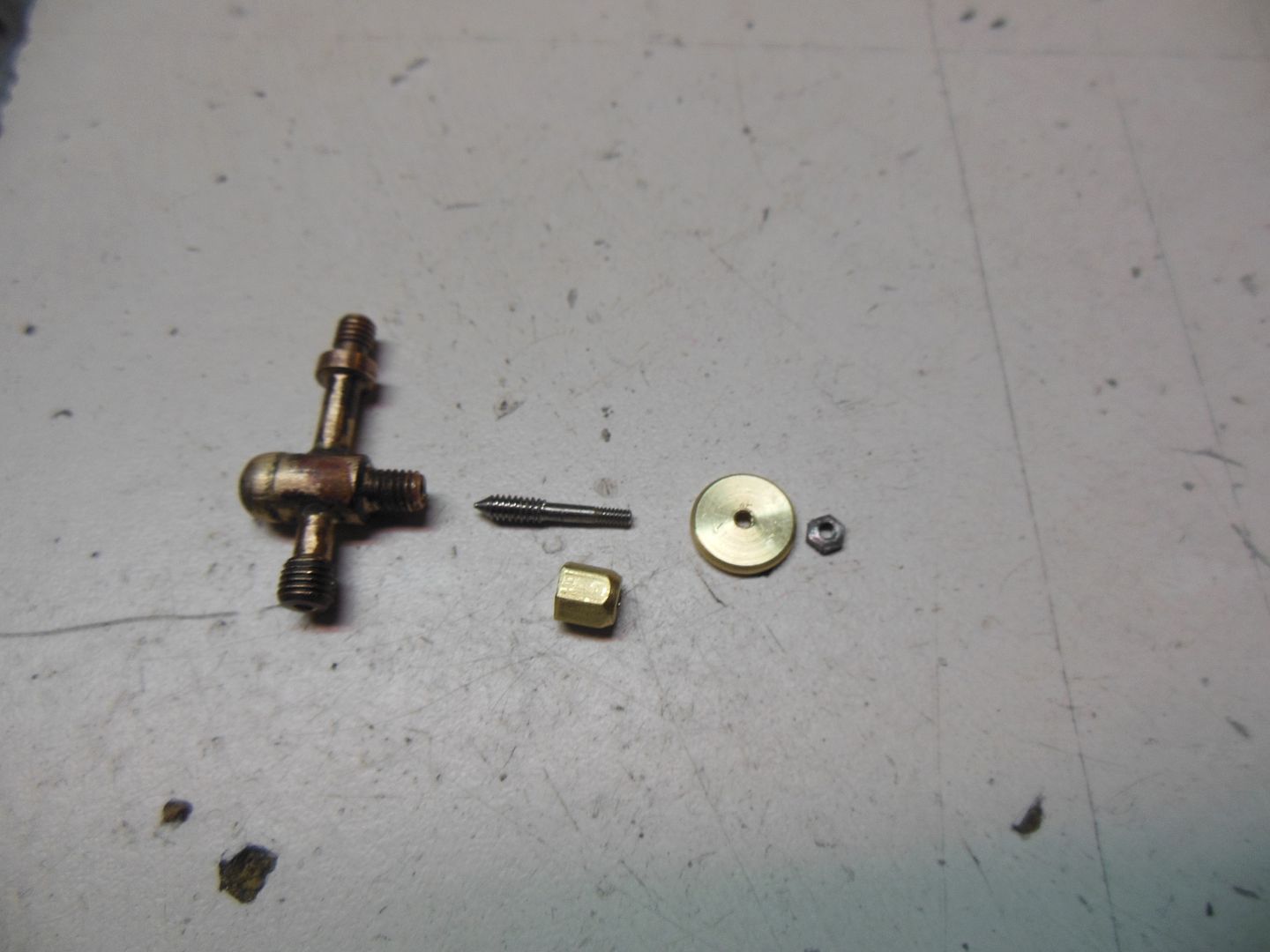

Moved on to the blower valve, turned a bit of bronze to size, threaded the outside for the bonnet, drilled and tapped it for the spindle,

and moved to the mill to cross-drill for the inlet and outlet while still on the parent material

Cut it off, and put it in a collet to trim to size and drill it out for the insert with the various passages required

Having neglected to take any pictures of the inserted bit, here it is with the insert and the inlet/outlet pipes (simple turnings, threaded

and through drilled) silver soldered in place, and the bonnet nut, the spindle turned from some stainless, and the handwheel & nut

Those of you familiar with the "words and music" as written by Mason will recognize that I'm really going back and forth with

regards to the order of construction here, simply a question that I tended to skip ahead when missing the material for various bits.

I've now received what should be the LAST order of material for the project, so am catching up... will now go to the valve & piston rods, a piston, and then we'll be in the happy position of running the first test on air!

Joe