Fizzog

you are correct there is a decimal point and your math is right.

My point or more sarcastic satire was at the fact that i had to use this tool that is flawed and i have the correct tool that is or was not then calibrated, i have since remedied my problem. And your not butting in your comments and observations are always welcome, i see your a new member thanks for joining and welcome to our little club.

Pete.

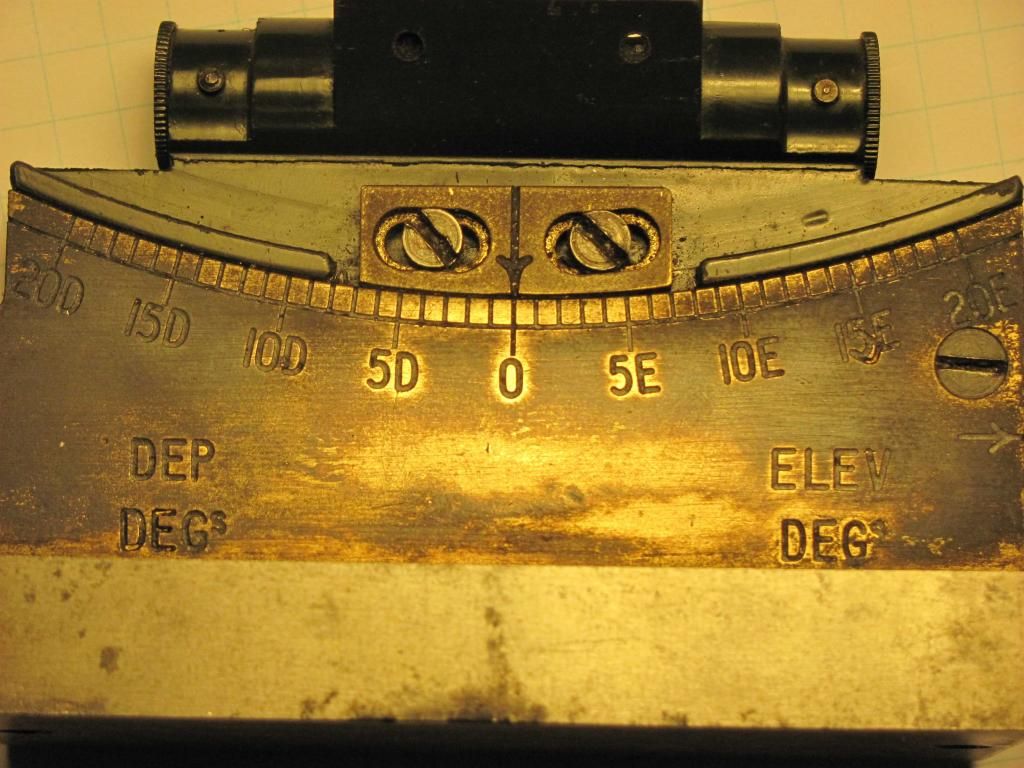

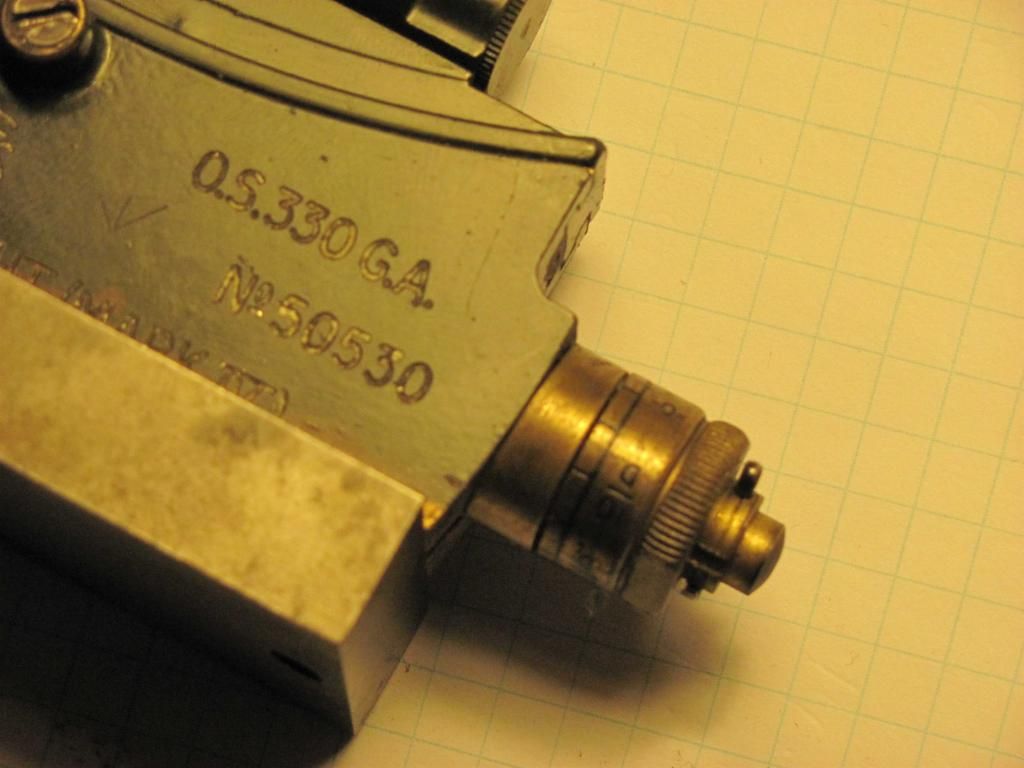

here are some close ups of the inclinometer.

I have owned this from 1985, i was working in Newton Abbot with an engineering company i just started working for designing Flour bagging and stitching machines for Hovis bakeries.

How i acquired it was the old timer i work along side with was just about to retire and we become very friendly, i found out he back in the day was a chief engineer in the Royal Navy from Plymouth ship yard hence the MOD marking etched in the side of it (the arrow looking down). I just turned out of my apprenticeship and I was at awe of his knowledge, he took me to his own shop where i saw mountains of surplus Navel equipment left over from the war, he was quite the tinkerer.

although he never told me this i do believe this is a gun sight to hone in within its 20Deg Range, what i have researched is that it sat on a plinth where on the side it read 1 divisions of a degree then to refine to minuets this came into play I maybe wrong, if i am i welcome the facts.

It has always been in this form i have never tampered with it. all i can tell you is it get used about once every 3 years on average, when like this example its priceless. BTW my Rabone mentioned in the beginning of the thread came from him to, this unit was made in 1944 the Rabone was made in 1945.

one other little thing was he offered me a box of electrical screens and parts, he told me that they were all prototype equipment for radar from the early 1930ies mixed in was Sonar parts too, the official radar did not go on line till 1936, i kick myself now for not taking them considering the importance it played in the Battle Of Britain.

One lives and learns.

Anthony