Hi all,

Looking into the 3 bolt mod for the head as suggested by Joe, I decided to take the head off again and do the mod as well as the tramming aids one (well published on the web). The mod uses the two T bolts that are included in the tool kit to add two additional fixing bolts to the tilting head.

Using a template the two additional holes was hand drilled in the head. The same template is then used as a guide to install the bolts,.

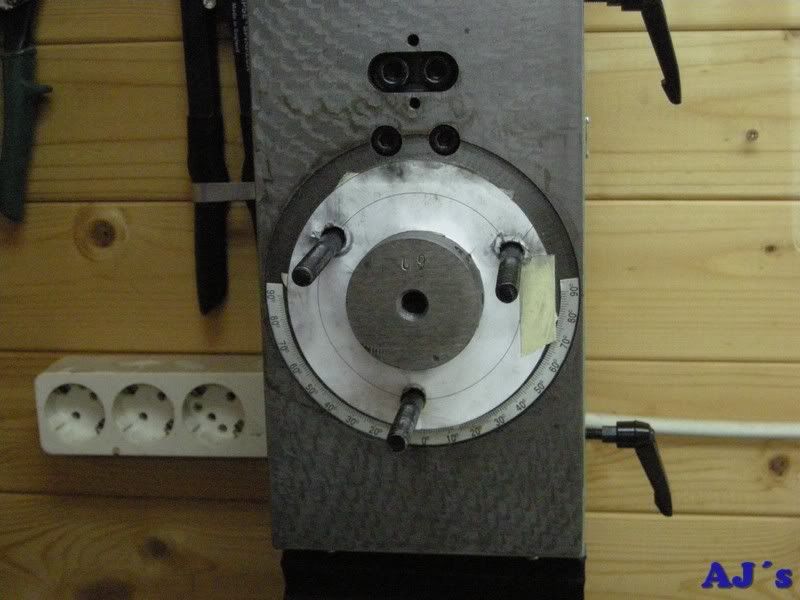

The tramming aids are basically two adjustable supports mounted at the top corners of the head slide. Once set and locked they can be swung out of the way to tilt the head and brought back into position to tram the head. As I do not have any collets yet, the support were hand made and the actual mill used to drill the holes.

Peter,

With the head off I took some pics of the strut mounting. The top is just a rectangular block mounted below the head lead screw nut. At the bottom the ball end of the strut just screws directly into the cross web of the base.

Next up tramming the column and the head.

Abraham