Hope this is Mad enough.

Made this thingy a few years ago: the idea came from a commercial item I saw for sale at a laughable price. It was made of plastics, and had the 'blades' attached through a single pin.

Having them attached on both ends helps a lot WHEN (not IF) they snap.

-- USUAL DISCLAIMER APPLIES --

I mean, that can be really dangerous (though safer and easier to use than the cutting disk, especially when there's tall grass mixed with bushings, IMHO).

The six hardened steel pins were kindly supplied by an old VHS player and cut to length by making use of a thin cut-off wheel(*) on a Dremel.

(*) OK, more than one.

One end of the pins was slightly ground tapered on the lathe (to ease their forcing down into position).

There might be safer ways of doing that, than a hand held Dremel while the pin was spinning into a collet.

No wheels were broken, tho.

Complete!

Ready to be tested on the field.

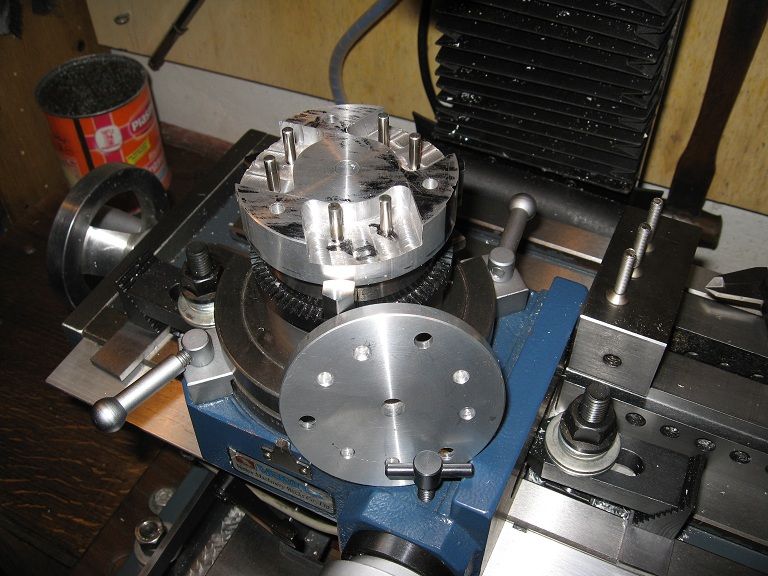

A snapshot of my beloved hydraulic press, showing the head with the hardened pins already forced into position.

The 8mm rod showing at the bottom of the head was used to keep the body and cover aligned, while forcing down the pins in the press.

Another view of all the parts.

Marcello