Kwackers,

much depends on the quality of the C.I. You're using.

The conn rod cap I used for an Elmer's cylinder was of the highest quality, it came out so mirror like I will never manage to take a picture doing justice of it.

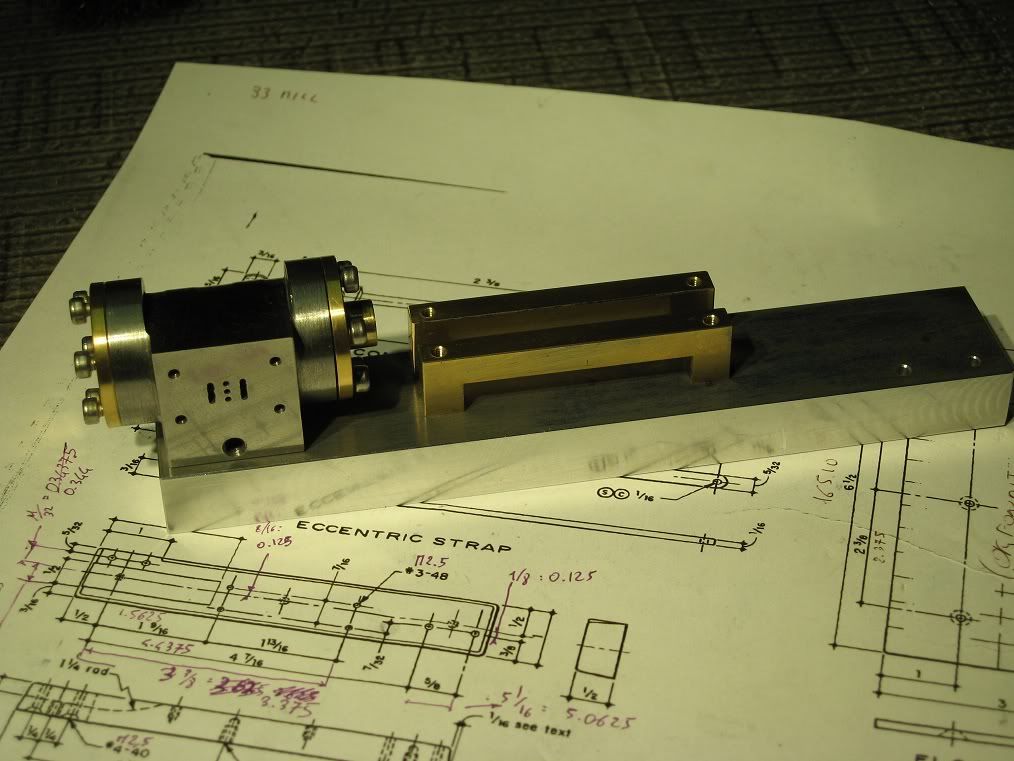

Here's the best my camera could gain, maybe it will earn autofocusing skills in time: still, with a bit of effort, You can see the cloth texture on the valve face.

If that's enough, I got that result by putting a sheet of sandpaper (the finest grade I had) on a flat plate (plastic ikea cutting board) and slid the face on it till I

removed all the tool marks. Next, I put another sheet of the same grain, which I had already worn out while polishing aluminium. The 'final touch' came using

printer paper as a support for Dremel polishing compound (anything of that kind would do, I suppose) mixed with thin oil.

It was some time spent into useless elbow work, as both the mirror-like faces won't be visible on the finished engine. The rounded parts could be made so on the lathe,

by wrapping the sandpaper (and then the 'polishing' paper) on a lathe tool blank, but I don't think I ever bothered with them.

Removing that black powder deeply embedded into nails and skin will take days, however frequently You wash Your hands.

Marcello