Pete,

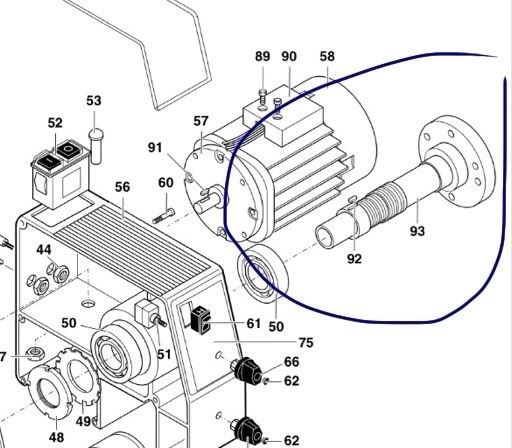

Pardon me for my ignorance. When you mentioned spindle nose, are you referring to those with threads on it? If it is, I don't have any. The round plate is where the chucks, centre turning attachment, and face plate are attached to, using the M6 bolts. From the exploded diagram in the manual (all parts labelled in Germans), this round plate is part of the spindle. to mount the workpiece directly to this plate, I'll need to drill the 3 or 4 clearance holes right through.

The plate measures about 100mm:

I did something like what you discribed on my Sherline before, which has a 3/4-16 nose. Once I've the thread done in the middle of a work piece, I was able to machine the face and cylinder surface with it mounted on the spindle nose.

The steel stock I bought:

I'm trying to figure out how to start...

Regards,

Wong