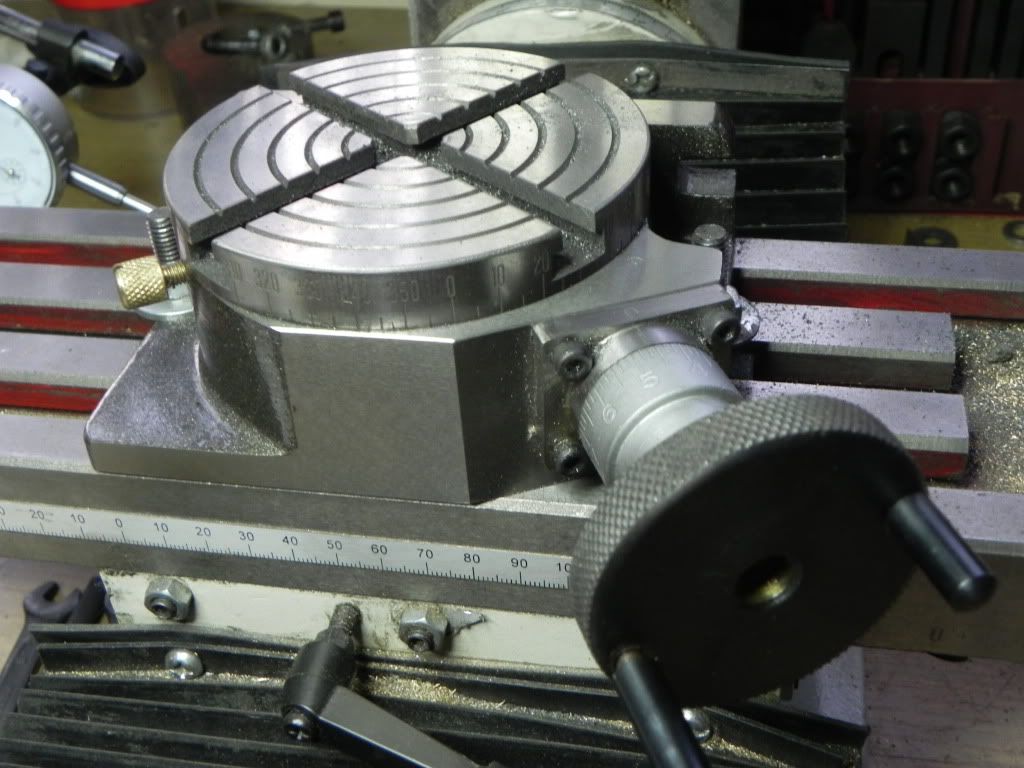

For a wail ago I brought a round table here in Sweden, not a fancy one, it was radar cheap.

I discover that in the middle it was a 8 mm threaded whole.

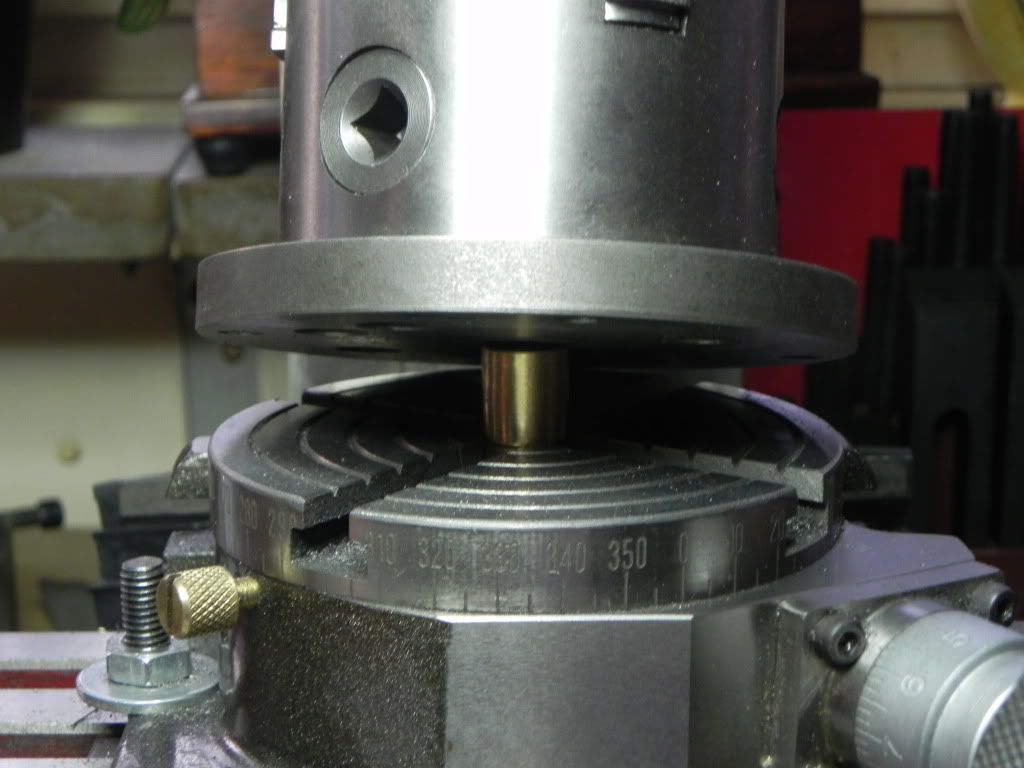

Then I was searching for a chuck, and found one in USA. The chuck come with a back plate and after some turn on the lathe it was ready to use.

But it was impossible for me to get it in center. Iíll tried times after times but Iíll never got it right.

I was very closed to write to you and ask for advice, but one night I wake up and I have an idea.

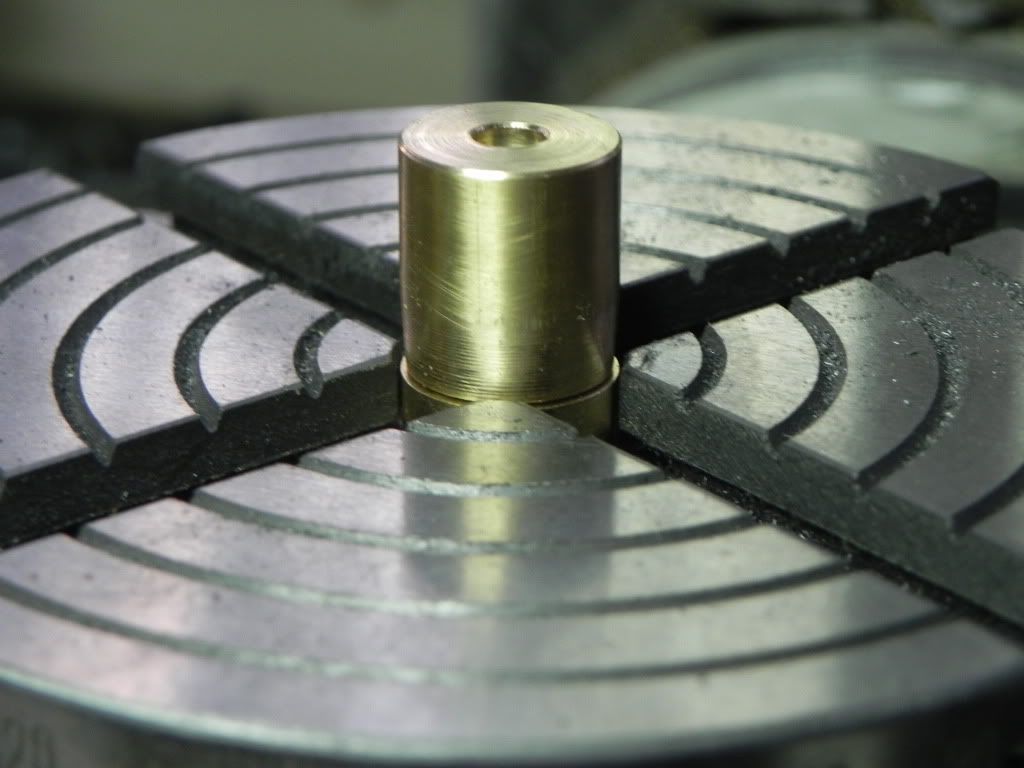

The same day Iíll begin to make a jig of brass, threading 8mm and in the middle a 4 mm silver steel.

Then I mount it on my round table..

.. and I have to make a small tool for fasten it, and then I measured the difference when I turn the table round and it was just 8/100 mm so I was pleased.

On the jig I can then mount some brass shaft..

..and it fit very well to my chuck. (of cource I can use many dimensions here).

Itís not the big thing that makes the different, itís the small one.