Hi all,

Finally a little more progress to report, I really know how to make things difficult for myself

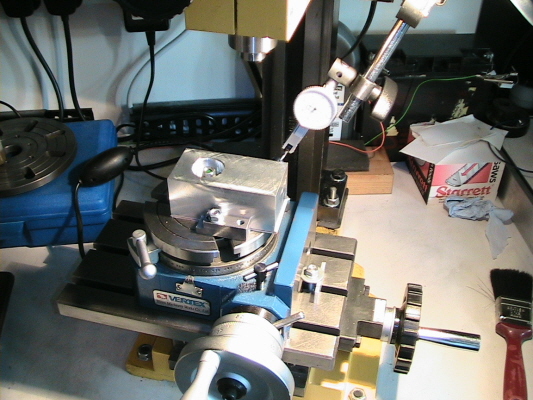

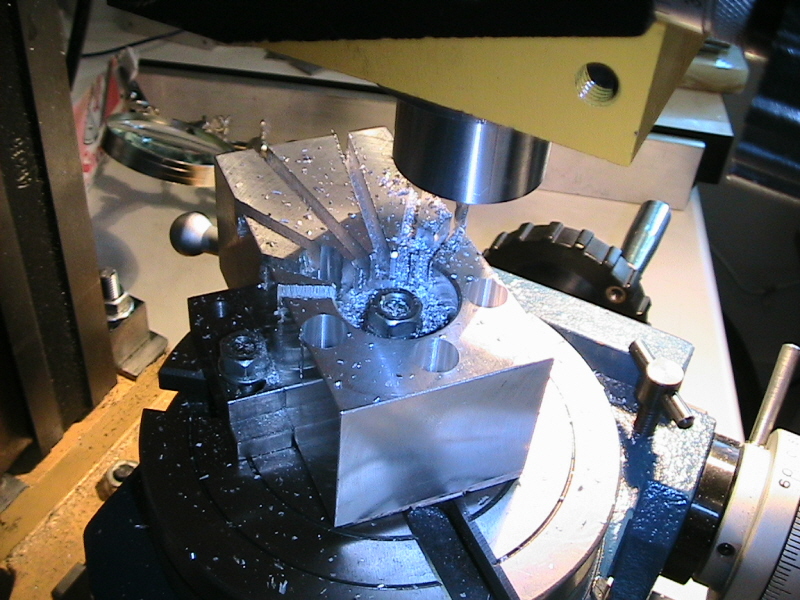

Set up to mill all those fins and 5 holes.

Why 5? I hear you ask, cause I thought it would look nice!

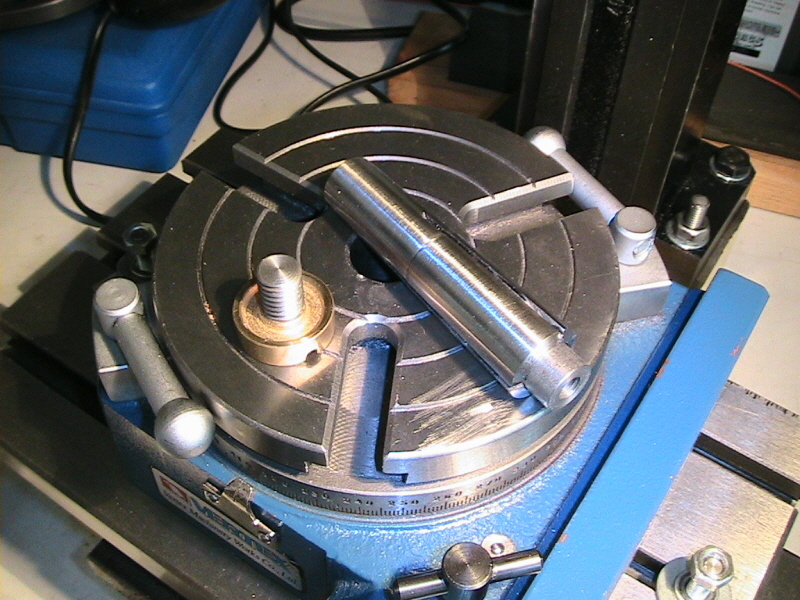

First I used an MT 2 collet and the little draw bar I made to fix a 12mm slug with M6 studding into the RT.

I then centred the 12mm bar to the spindle using the X-Y table and zeroed both handles going clockwise (as I always do so I remember where I am if I leave a job til the next day.)

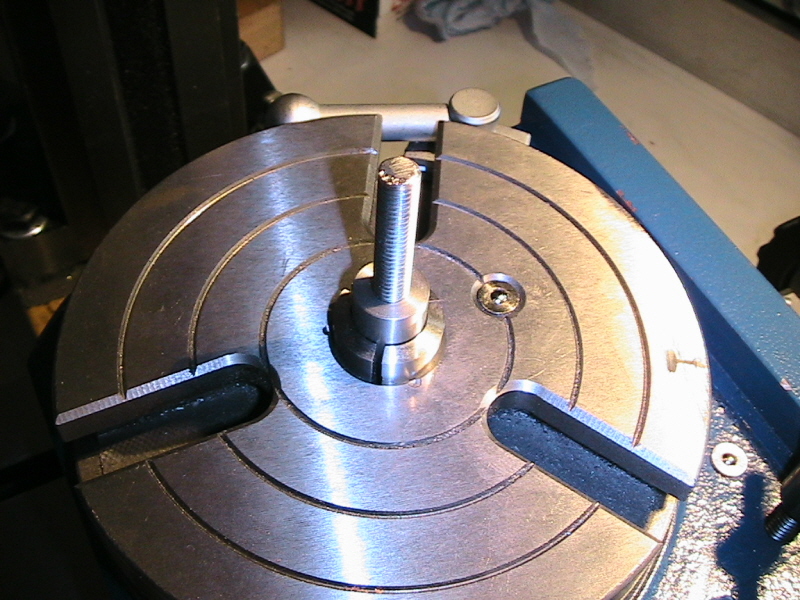

Then mounted the part and centred that, tapping until it read true when turning (by hand) the spindle.

As a check spinning the RT it was all within .05mm.

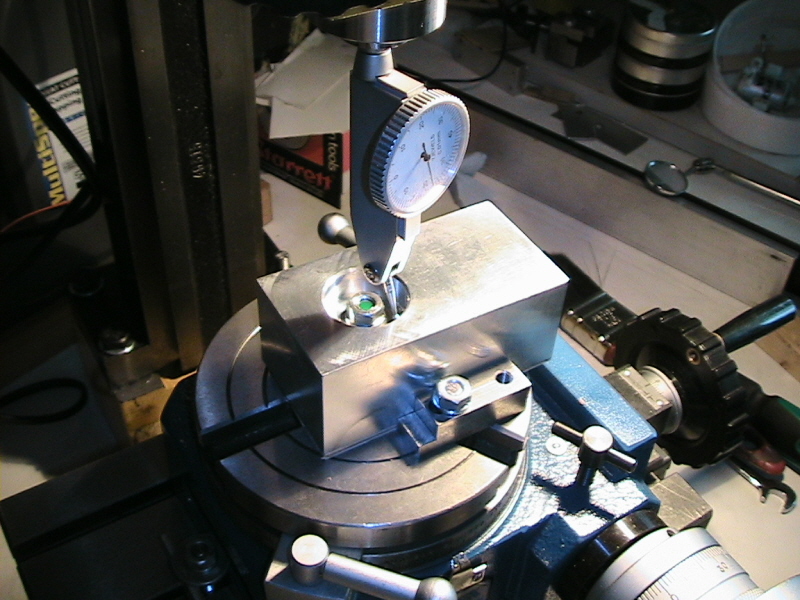

Then needed to set the edge of the part by rotating the RT and traversing the X until it clocked zero (making sure I didn't mess up the X collar setting.)

Noted the whole degrees reading on the table and zeroed the RT handle collar.

Then I could drill, counter-bore the holes and mill the slots, all using the centre of the main bore as a reference.

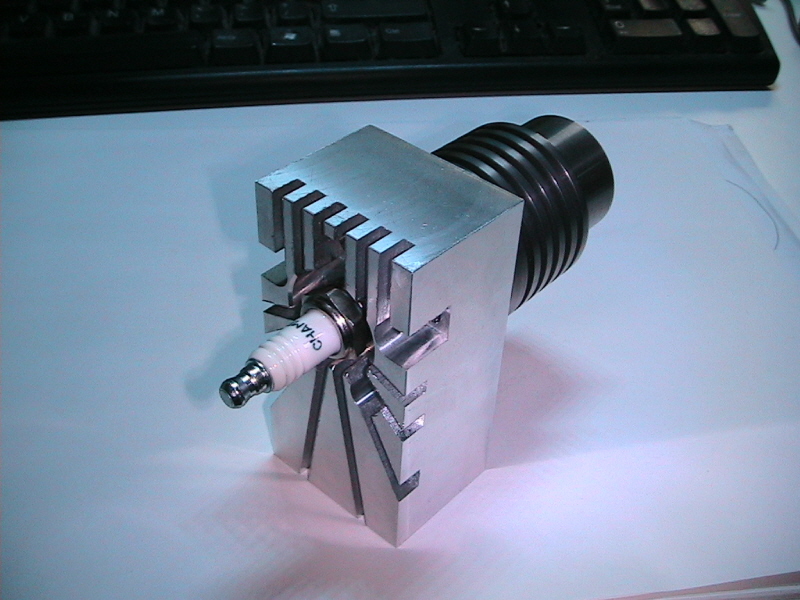

Finally couldn't resist a little mock up shot with the plug in, haven't even taken the burrs of yet, or done the top fins but I was quite pleased with the way it went.

FEW!

Next time I post a plan with all them bits to it - someone stop me! Please!

Thanks for looking again,

Steve.