But why move it AT ALL?

For one thing, it's easier on smaller lathes.

You can cut it just as easily with the compound left alone, why confuse yourself by moving the compound, it just adds confusion and does not help at all.

If it confuses you then do it the way you like. Most of us aren't confused by such a thing, and don't have any

trouble doing it with the compound set to 29.5. There's nothing hard about it.

Just leave the compound alone and cut straight in, it works without all this black-magic art that others will try and shove onto you. OK, OK, so the book says to do it this way, well, when was the bloody book written and maybe the tooling has improved slightly since then too.

Nothing "black magic" about the simple act of slewing the compound around. And, the people who wrote the book also made the machines.

I don't really understand your attitude on what is just your second post to this forum. You don't need to go knocking the way

other people do it, which is probably the way they've been taught, and which has worked for long before you were born.

Jason; It would be best to practice on some outside threads first like Mark said. At least you will be able to see what is

going on and learn what to expect. Then move to the internal threads. A few practice runs will save you some scrap. You

don't want to ruin your flashlight piece while learning this. Cutting threads is a common thing, but like anything else, the

first time you do it you will be feeling like you have to watch four things at once. Run your lathe slow. Slowest speed you

have will probably be best.

Pay attention to the threading dial when you first engage the lead screw, and leave the tool bit

a little way to the right of the cut when you are engaging the screw. That way, if you miss your mark on the threading dial,

you will have time to disengage before the tool meets the work piece.

Make sure you have some space at the end of the thread for the threading tool to run off a little. You don't want it crashing

into a corner in the work piece.

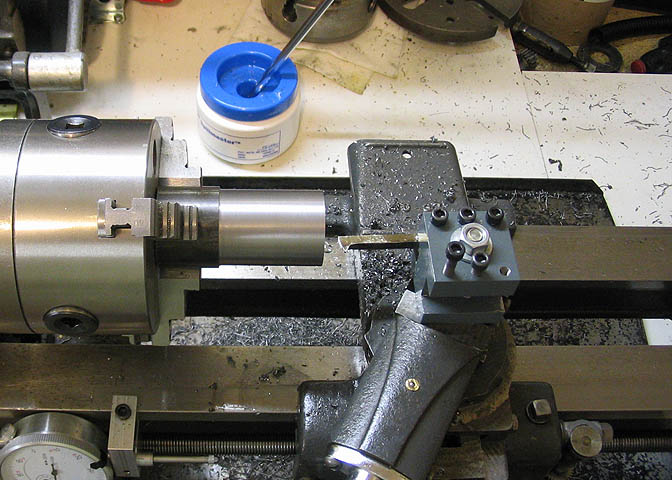

I set my compound like this for doing inside threads.

It's just convenient for me this way, and have done it like this for many years. You could also set it over towards the back

of the lathe, but it's a little harder to see the feed dial.

Once you're set up, zero your cross slide before you make your first cut. Then, after you dial in the compound and make your

first cut, you can use the cross to move your tool back and crank back the carriage for the next chip. When you have the carriage

moved back, return the cross to zero, put the next cut on the compound and make your next chip. This way, you don't have to

remember the setting on the compound slide for each cut. Just dial the cross slide back to zero before each chip and the tip

of the threading tool will be back where it was when the last chip was cut and you can dial some more on the compound.

Feel free to ask more questions about this!

Dean