I'm really glad everyone is having fun watching me build this. Like many I also wish it was going faster. My day job and just things in everyday life seem to get in the way of quality shop time. But i was out there today:o)

I'm building a little drill jig to guide the drill bit when I drill my spoke holes in the rim. I am using some square stock. I held it in a V-block in my angle vise to drill the guide holes. I am compromising a little on the jig. For the big wheel the angle is about 2 degrees more than needed and for the small wheel it is about 2 degrees less than needed. There should be enough play in everything to make up the difference. Here I am centering the stock below the spindle of my mill.

To drill the hole I need a flat spot so the hole will start accurately. I mill a small flat, then center drill and drill it.

I then mill a little bit of relief in the middle of the guide. This way it can clamp down squarely and not rock. I do this on two sides.

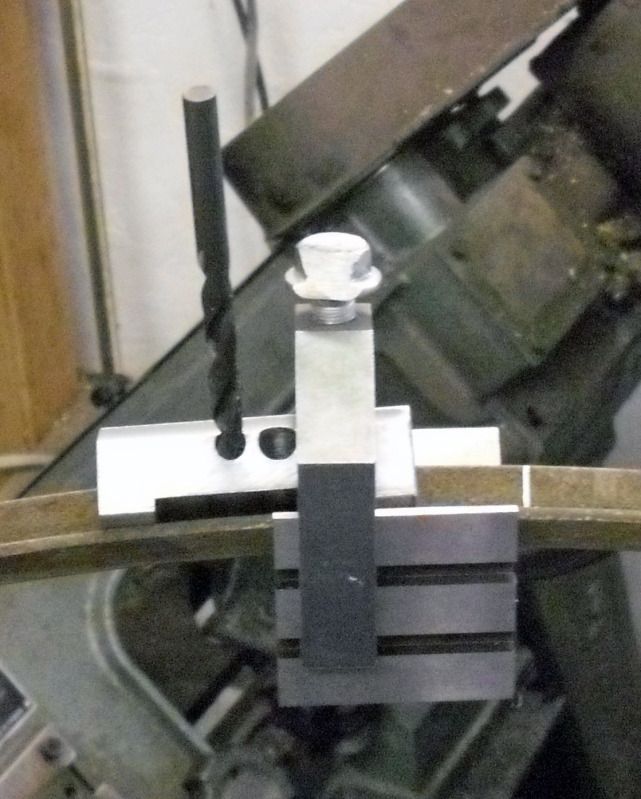

Here it is clamped to the rim. I can peek down the hole and align the guide with my mark then clamp it into place. The holes should all be crooked by the same amount:o)

Here's a side view.

Thanks for watching:o)

~Wes~