Well, I might get labelled a redneck here, but here is a mod that helped me immensley with parting off on my mini-lathe...

I had always had trouble with parting off. Going to a steel QCTP helped a bit, as did locking the carriage and the cross-slide. But it still wasnt good.

One day I came across a picture on the nudie-net (sorry, dont remember where) of a bolt, threaded into the bottom of the parting tool holder to give it some support. I needed a quick-fix right now, so I tried this little bit of "bush engineering", and it worked wonders! So well in fact that 3 or 4 years later I still havent prettied it up!

The pictures arent great, but you will get the idea. Here is the tool holder:

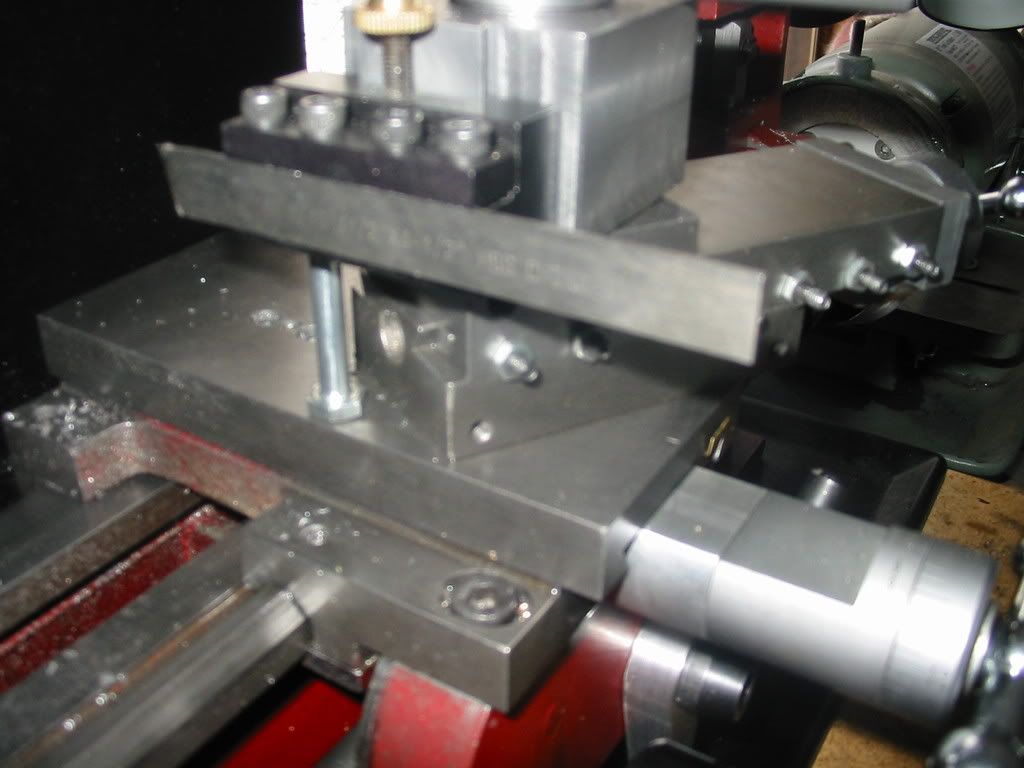

and here it is on the lathe:

The head of the bolt was faced off to give it a smooth sliding surface, and a jamb nut locks it rigidly into the toolholder. The bolt can be lengthened or shortened to allow for tool height adjustment. The bolt head slides smoothly across the cross-slide as you feed the tool in, and so far does not appear to have worn, marked or "hammered" the cross slide.

Sorry for posting such an ugly mod, I wouldnt have done so if it hadnt worked so well!