Thanks guys. The gearbox is probably one of the most successful projects I have done. I needed a slow but powerful reduction to the spindle for certain jobs.

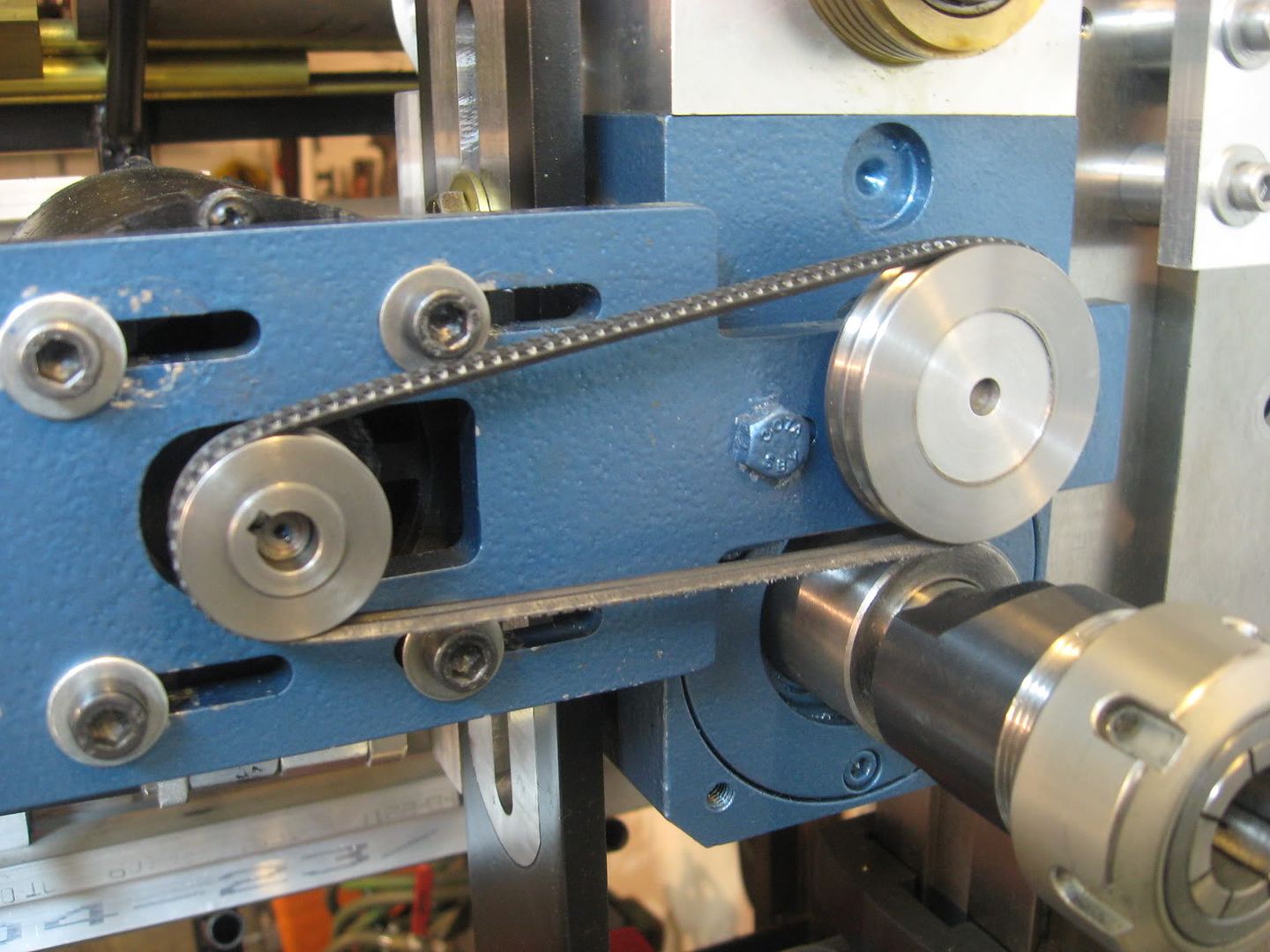

The machine uses the gearbox for the first 3 speed reductions. It has a high speed bypass setup as well.

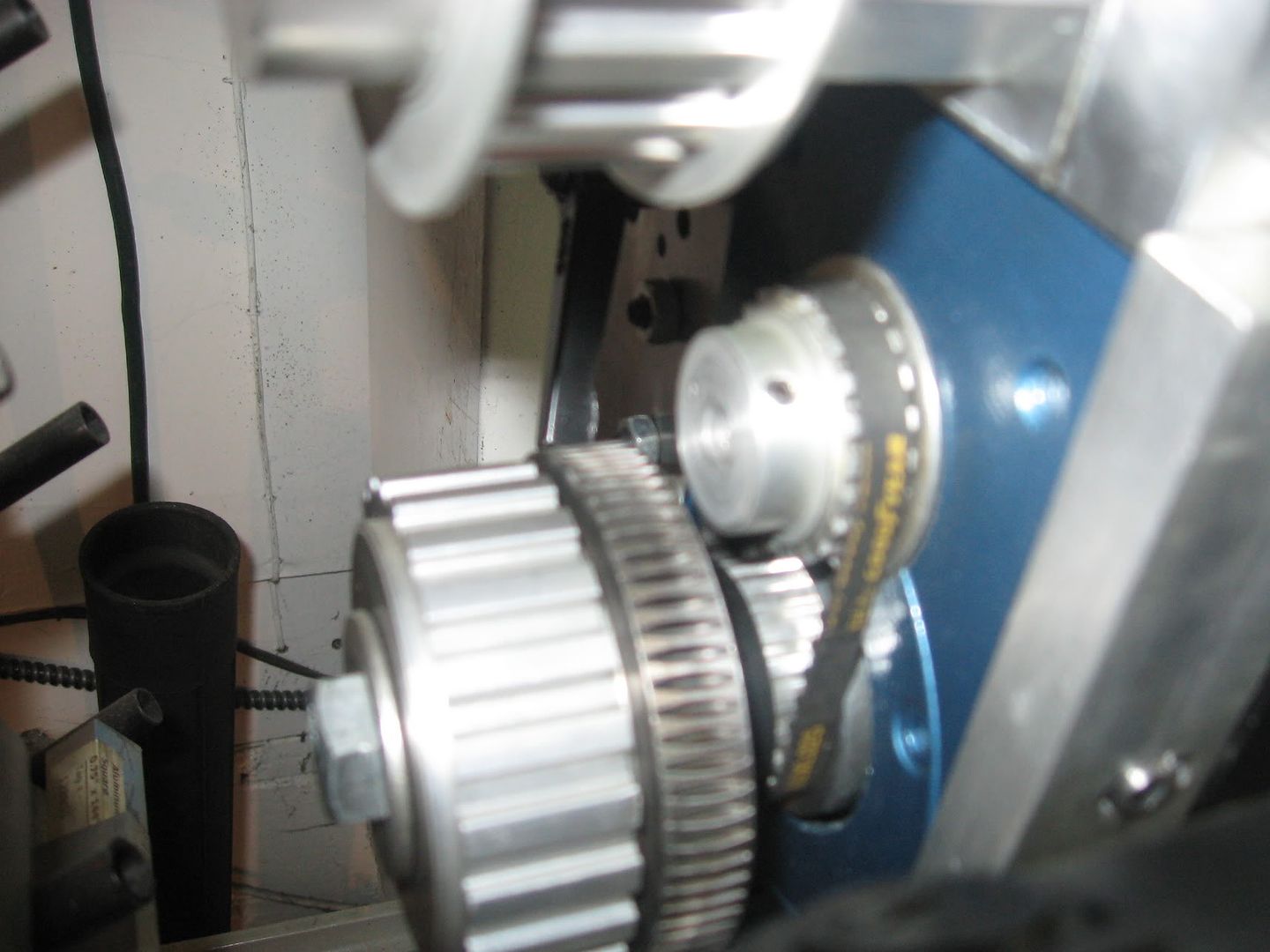

If you look at the pic of it installed on the mill you can see the unused dual groove pulley under the gearbox.The dual belts are removed from the gearbox and installed on that pulley. Then the large HTD belt removed from the output side of the gearbox. The spindle is then driven at a 1.7:1 ratio via the mid shaft in the head stock.

The 4 speed ranges along with the variable speed DC drive gives the following rpm ranges at the spindle-

1st gear- 0-75rpm

2nd gear-50-125rpm

3rd gear- 100-400rpm

4th gear- 400-2900 rpm.

belt setup for high speed ratio-

Rear of headstock , HTD belt removed and spindle then driven at a 1.7:1 ratio achieved by bypassing the gearbox. Sorry about the fuzzy pic,

Could we get you to post some pictures of the mill/lathe. It would be greatly appreciated.

Bernd,

yeah sure, I'll start a new thread on it.

Steve