So now we'll jump to the end of the project,

The machine is cnc'd presently in 3 axis. The table x and y and the spindle is cnc'd for continuous or indexing machining.

It's a cnc boring mill,indexer and lathe.

The planetary gearbox drives the spindle for 3 reduction ratios and a 4th higher speed which bypasses the gearbox.

The machine has a good rpm range from 0 to 2900rpm.

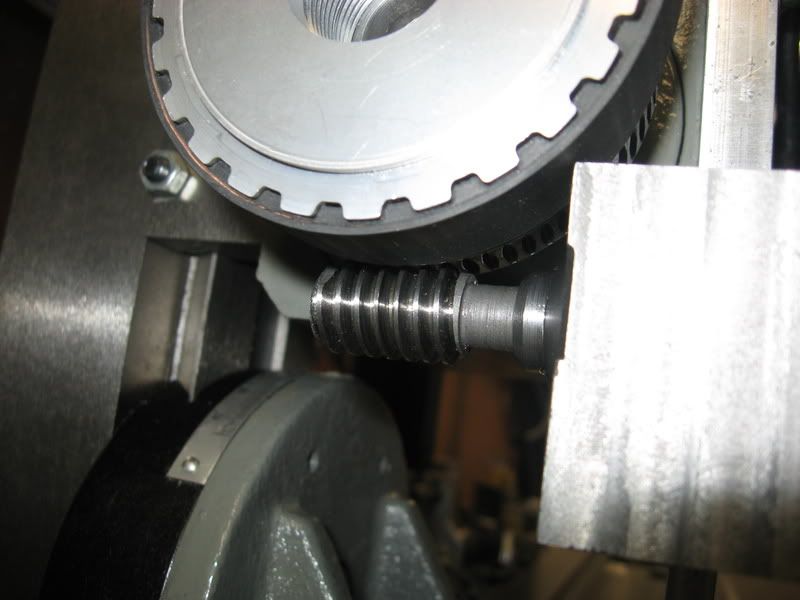

The spindle has a ring gear on the left hand side and a stepper motor is mounted on a eccentric with a worm gear drive. Rotating the stepper engages the spindle and locks in place with a detent ball.

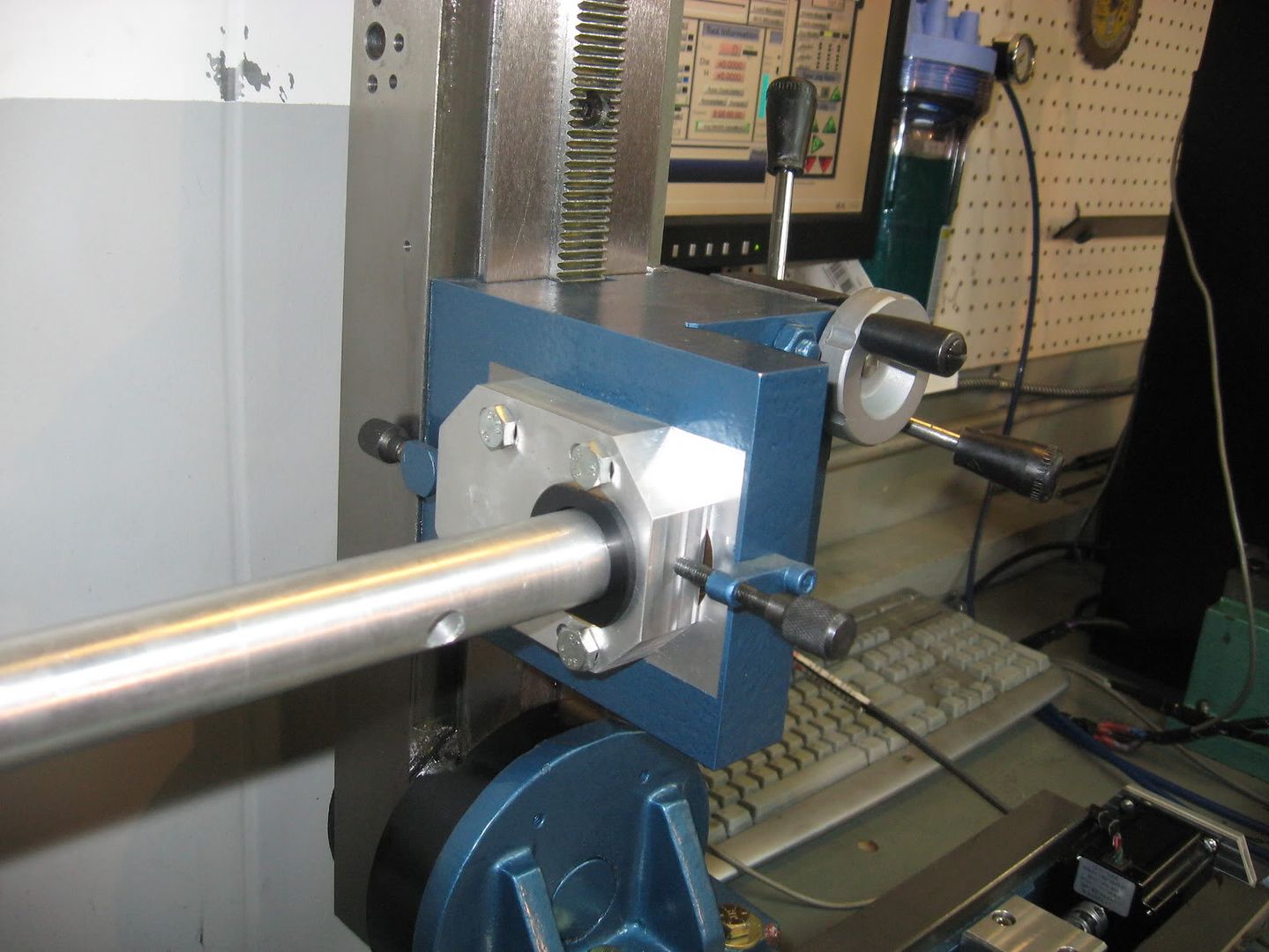

The outboard column is used to support line boring bars or arbors for horizontal milling/sawing. It is fully adjustable to keep the work or tooling straight and uses a rack and pinion for movement along with a fine feed. Bushings are replaceable to suit whatever size needed.

The headstock uses a acme screw and delrin nut and is pretty much backlash free.

The headstock also has a separate brace to further improve rigidity. The deflection at the spindle end is better that my x3 mill.

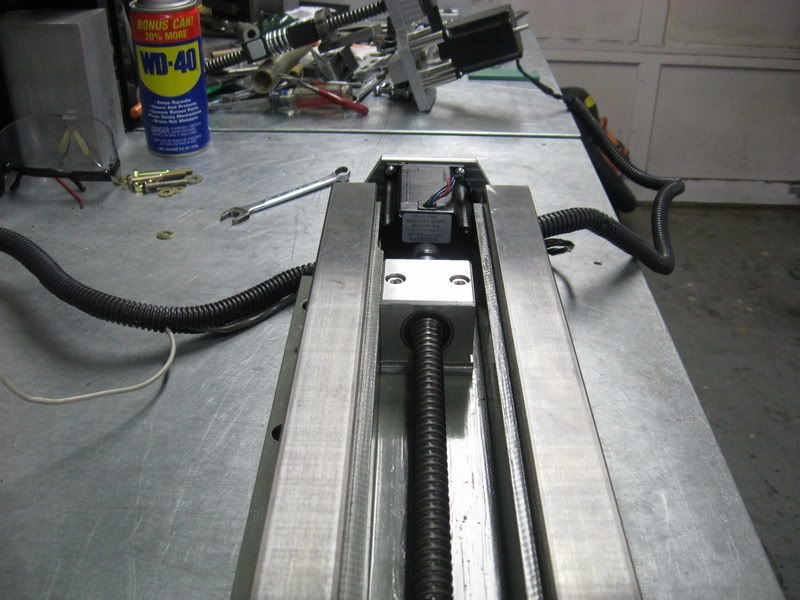

The long axis is driven by ballscrew with dual preloaded nuts. The cross slide is driven by the same arrangement and also use linear rails/trucks. This is going to be changed soon to a much larger table and dovetail ways.

I also built a separate mill/drill head with a quill that can be mounted on the table for many uses. I made it from an old drill press head and made a new spindle with integral 3/8" endmill holder and good bearing support.

The machine-

Here is a video showing the planetary drive system in action-

Here are some of the very first videos of it in action in lathe mode-

Steve