Hi all,

New thread started. Faithfully trying to follow the processes in this thread

http://madmodder.net/index.php?topic=627.0Well the weather has been too good to be working in the workshop and I have had to do some proper work today

but thought I would post my progress so far while I wait for some paint to dry.

The story so far, after reading Bogs' superb thread about fixing Darren’s lathe I decided to have a go at doing the same to my trusty 7x12, I'm coming to realise that perhaps I have been a little too ambitious so this could all end in tears.

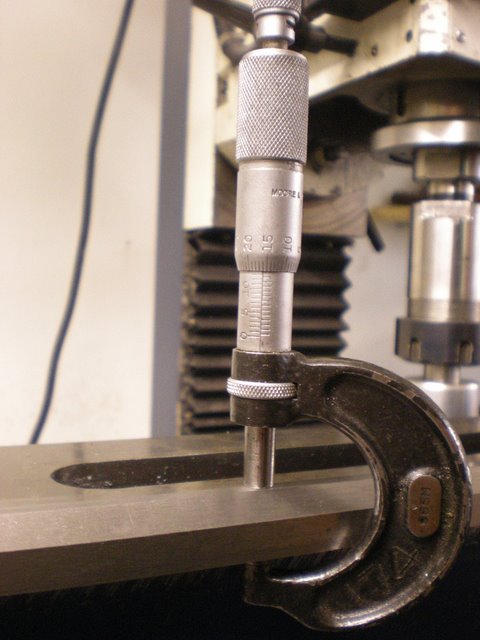

My lathe had a taper of .24mm end to end when measured between the top and bottom of the ways (where the Gib strips run) but having spent a fretful afternoon skimming them down to .07mm taper over the length of the bed. Actually not the full length as I didn't skim the area below the head stock.

I didn’t take any pics of the set up but here is something that shows how small my mill is compared to the casting.

These 2 pics are taken about 10" apart

Not too bad?

This is the machined area after a little dressing with some 800 wet+dry paper soaked in oil wrapped around a piece of square bar (thanks for the tip John), The small machining marks are hardly visible to the naked eye but the camera seems to exaggerate them.

I hope to get a bit more done tonight, perhaps squaring up some stock to make the new carriers or maybe I’ll just take a deep breath and relax for the evening and make sure I know what I am doing next.

Cheers

David TS