Hi all! Well I finally got a chance to work on a tool instead of moving it. For quite some time I've wanted to upgrade to the large south bend dials. So I started Ed Godwins upgrade

http://www.wswells.com/projects/projects_index.html which includes adding thrust bearings.

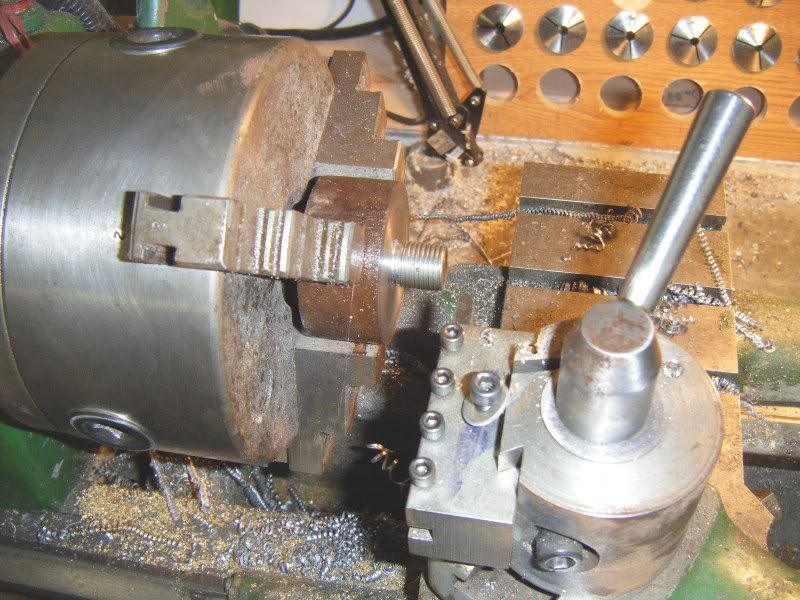

Started on the bearing housing....

Started threading....

Now to test the fit.....

No 9/16-18 nut, or die, or even a tap to make a gauge.

After a couple smokes and some head scratching I reasoned that as long as I didn't move the tool post or alter the gear train I should be able to remove the compound, check the fit, and reassemble without losing the thread.

So pulled the compound screw, pulled the compound off it's dovetail, checked the fit (too tight!), reassembled, and amazingly picked up the thread right away.

Took off a thou or two more (still too tight!), repeated above process to the point of lining up the thread dial and

Somehow I'd managed to disengage the dial!

Thus ensued about two hours of fiddling, refiddling, and general butchering of the poor thread I'd started. Finally ended up with something that looked like a thread, only uglier.

But...

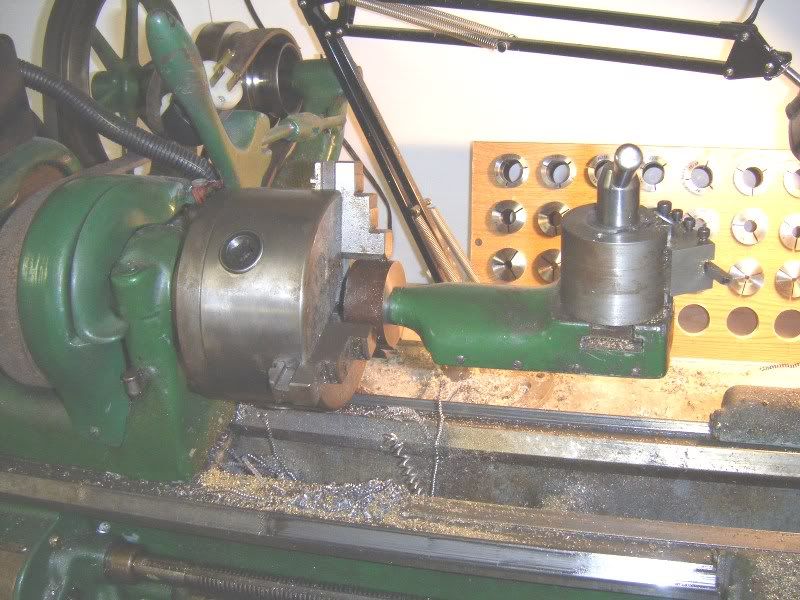

It fits

No shakes, no rattles, and no wobbling!

Can't machine the other end until I get the screw made. Hmmmm, first step - cut a 3/8-10 Acme thread.

I believe I'm done for the night!

Cheers

Jeff