This is how I turned a Morse taper, for no particular reason I just wanted to test the procedure!

I centre drilled a scrap of steel and mounted a dead centre between centres, you can see what I mean.

Then I turned the compound to be approximately parallel to the surface of the dead centre..

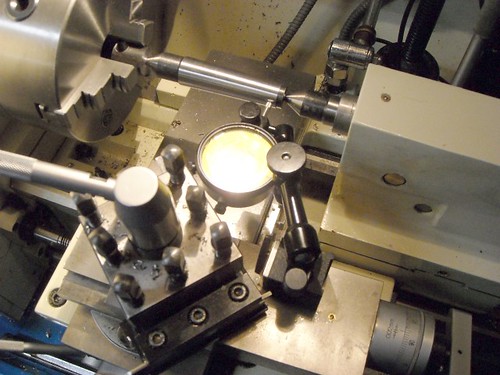

..... and mounted a dial indicator on the compound (it had to be on the actual compound not the cross slide).

The next step was to wind the compound back and forth adjusting the angle of the compound until the dial indicator showed no movement over the length of the taper.

Time to cut some chips...

... I had to go very carefully taking only light cuts as the position of the compound prevented supporting the end of the work. All cuts were made by advancing the compound being careful not to move the saddle or cross slide. The cross slide was advanced at the beginning of each cut otherwise left strictly alone and actually locked for the last couple of cuts.

Time to taste this pudding .......

... slipping on the MT5-MT3 sleeve that came with the lathe.

A perfect fit, I thought I was going to have difficulty getting it off!

No final adjustment needed at all, just a quick polish up with some emery tape.