As there seems to have been a bit of traffic on the forum lately, about case-hardening, I thought I'd add my two pennyworth.

Nothing special, just an everyday job from work. But I had my phone with me, so thought I'd take a few pics.

The problem.The threads on the end of this spindle have been damaged. Doesn't look much, but I've chased them out with a fine file, and still can't get the nut to spin on freely. If I force it I'll end up galling the thing up properly, and probably scrapping it. The thread is M16 x 1.25. An ISO-fine thread. There isn't a die nut anywhere on the firm to fit and the machine it's from needs to be back in action as soon as possible. Local tool suppliers say minimum 24 hours to get the right size die.

20170718_103622

20170718_103622 by

Mick, on Flickr

Aw, nuts...Have some spare nuts with the right thread, so it's time to improvise. Cut a diagonal slot to give a good rake angle.

20170718_103908

20170718_103908 by

Mick, on Flickr

Got gas.Warm to a nice cherry-red.

20170718_104357

20170718_104357 by

Mick, on Flickr

Old, but still useful.I'm pretty sure this can has been with the firm longer than I have. We may retire together.

20170718_110239

20170718_110239 by

Mick, on Flickr

The magic happens here.Add a little of the voodoo powder and re-heat, until it's all been absorbed or burned off.

20170718_104456

20170718_104456 by

Mick, on Flickr

20170718_104736

20170718_104736 by

Mick, on Flickr

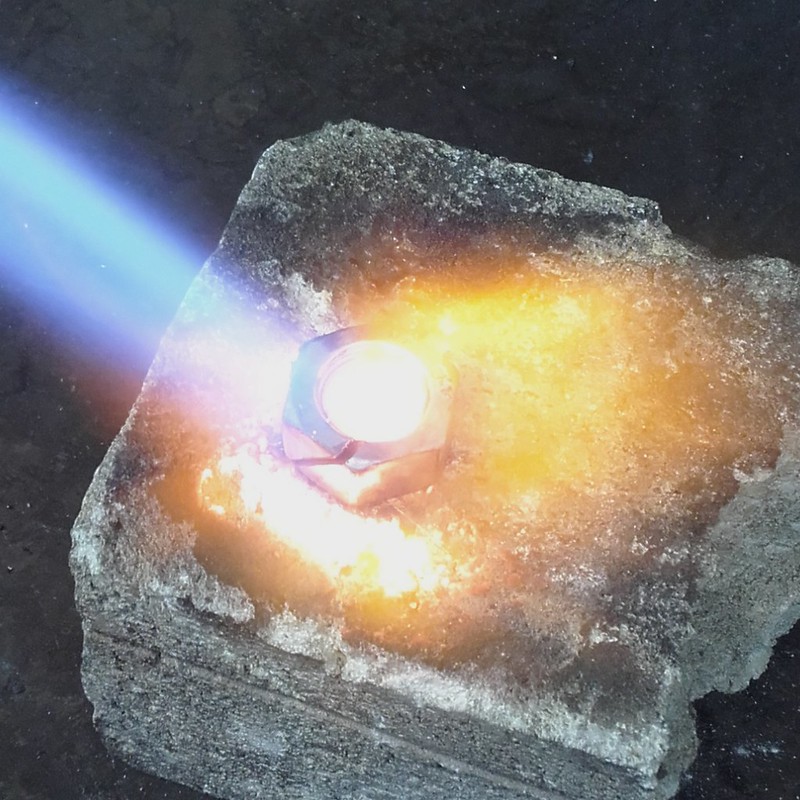

Suddenly, we're cool.The quench. For some reason my camera makes this look like it's white hot. It was actually a bright cherry red.

20170718_110407

20170718_110407 by

Mick, on Flickr

To work.A quick wire brushing to get rid of the oxide scale, a dab of cutting oil on the threads, and feed it on. You can feel the difference, this is cutting the threads and making fine swarf, not just mashing the metal up.

20170718_105221

20170718_105221 by

Mick, on Flickr

Job done.The proper nut now runs the threads nicely, no binding or snags.

20170718_105820

20170718_105820 by

Mick, on Flickr

Soon the machine is back in action and everyone is happy.

“Super Fitter” saves the day, again.