Wayhey! I finally get to stop messing about with plasterboard and wood, and do some real machining for the office!! Woo!

OK, it's only a little TINY bit of machining, but even so, it's a good excuse to make sure the old CNC machine is still working (it is

).

So, take one shiny new blanking plate, and screw to a piece of sacrificial wood. Clip decorative plate to the top. Those clips are pretty sturdy, they'll stand up to the machining forces I'm sure:

Urgh, maybe not....

The cutter bit a little hard, the feed rate was a little high, and those "sturdy" clips got ruined. Oh well, lucky I bought 2 (just in case one got messed up...).

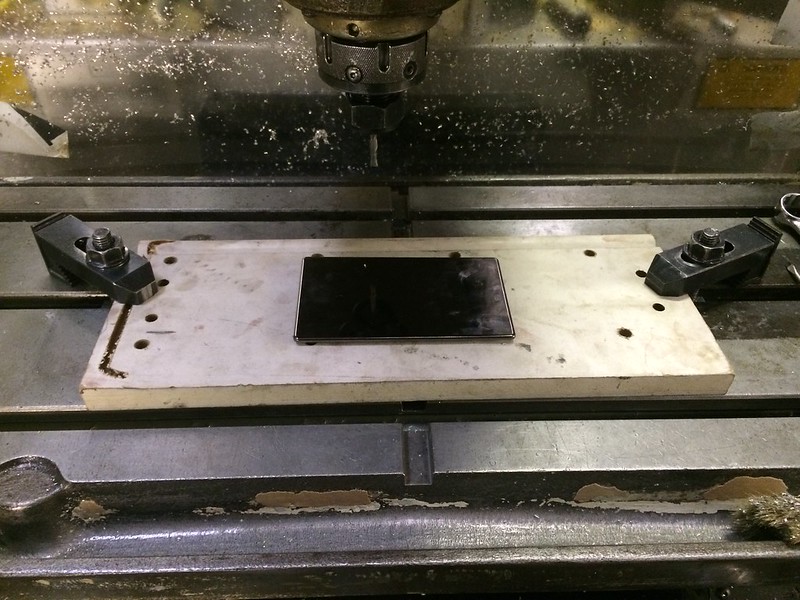

Second setup with some bodged up ali clamps to hold the decorative bit down, there's paper underneath to preserve the finish. Slowed the feed rate waaay down, and all went well:

A few seconds with the file had the holes cleaned right up. Then, the same ops on the actual blanking plate underneath. I'd hoped this would be a nice flat plate, but it isn't, it's got a weird shape pressed into it. Never mind, I can just squeeze everything in where I want it. So here's the finished article - note the minor "bodge" required to one of the plugs, to fit around the shape:

Of course, if I'd actually managed to hit the centre of the plate, instead of somehow being 2.5mm off in both X & Y, then I wouldn't have had that problem. Hey ho, maybe next time. This one's going to be tucked away under a bench anyway, so it's not like it's going to be in yer face.

So, one 4-way IEC C14 male plug on a 2-gang wall plate, looking pretty tidy:

Lessons for the next one:

- Measure the actual plugs, don't go by the drawings. The plug cutouts are actually slightly oversized.

- Don't rely on clips for clamping.

- Hit the bloody middle!

There's only one remaining conundrum... do I mount it vertically or horizontally?