As usual, curiosity got the better of me. Couldn't find anyone else had made a gear (Dremel Work Station) for the drill press. So dismantled mine, huh doesn't look so bad.... Then tried to push gear off shaft it was on !!! Won't budge by hand, arbour press with 10t hydraulic in reserve.

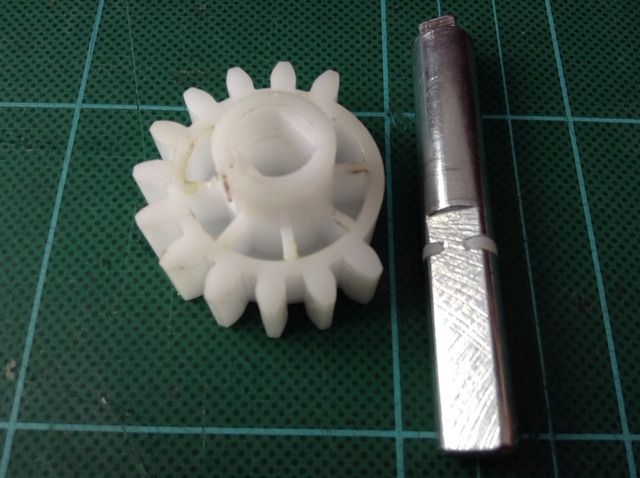

Success, kind of... Dremel in their wisdom mould the gear onto the shaft, see the white plastic left on the shaft recesses. They have a nice return spring for the gear, but its pickup is tiny and even on the nylon gear I have here it's showing signs of stress. For a printed gear I would add some bulk to the boss here for strength. Maybe get another mm of radius and fillet at the spring notch.

Since the gear is on a round rack, the gear teeth can be strengthened by making them follow the rack bar more closely, than being square cut as they are. I could also get a bit of radius at the tooth root which would help strengthen a printed gear.

As my gear is nylon I am starting to think we don't have the same drill press, so I will post this as a how too, re engineer a gear for 3D printing if thats OK Pete.