Right, After a quick private natter to Darren we decided that keeping all the power feed mod's together sounds good.... That said......

I've been a little busy

You've already seen the plate I started to make (if not... it's further back in this thread!)

Well here is the continuation of that....

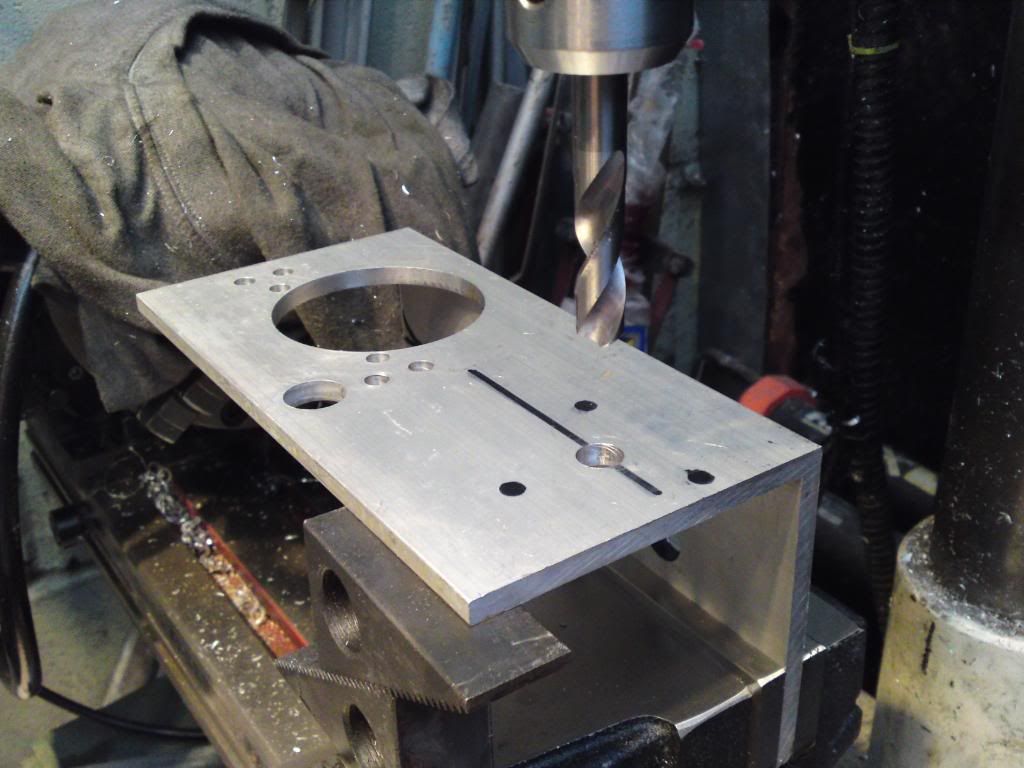

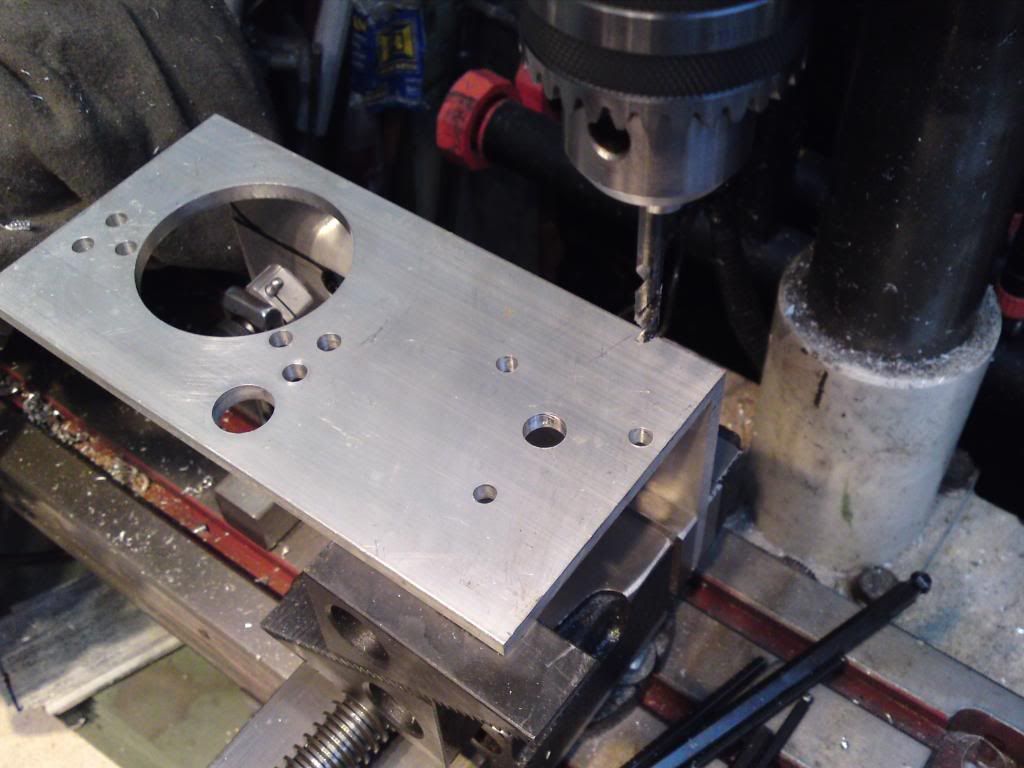

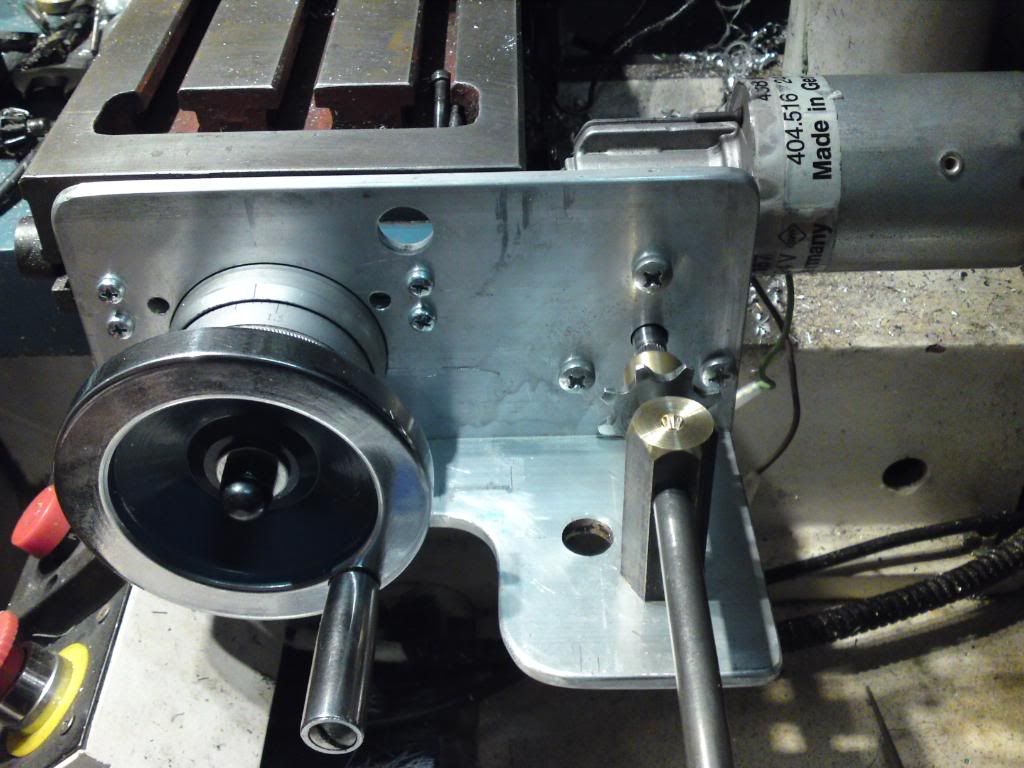

Motor mounting, first the 11.5mm hole for the spigot shaft to enter through, then the 3 mounting holes ..... Yes I know I'm a bad lad for the Heath Robinson way of marking and eyeballing, but it works for me most of the time!! As it did here. (I marked the hole points using the original motor mounting plate from the garage door op')

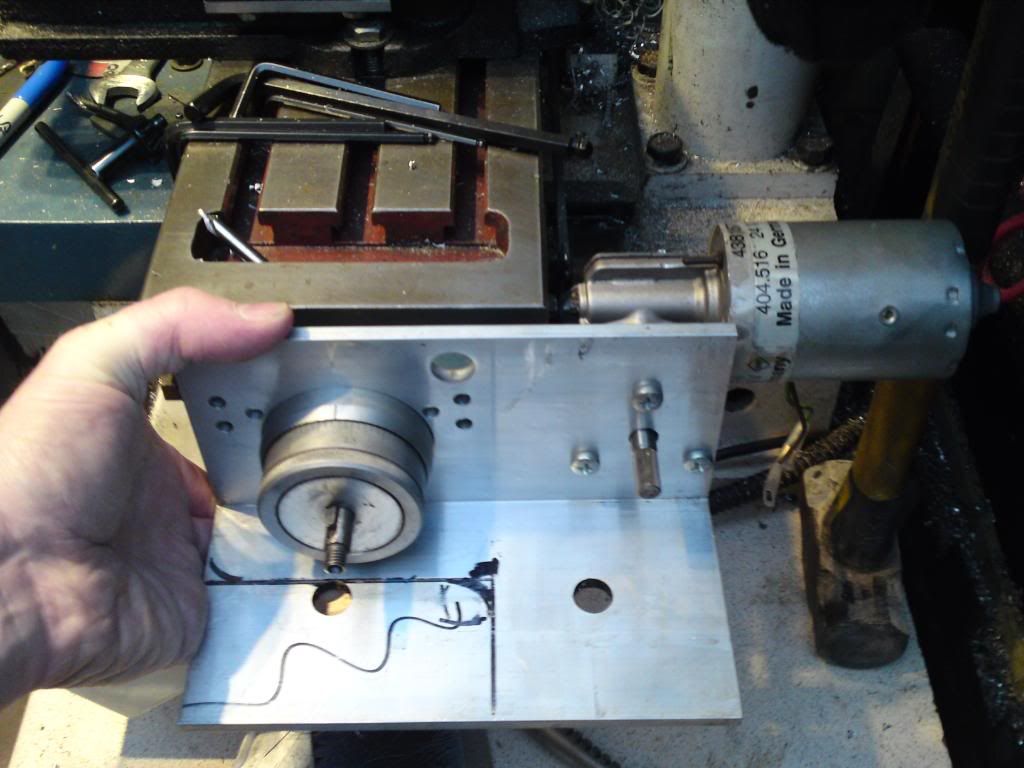

Then I robbed another part from the garage door op' the spigot drive doofor thingy (technically accurate I think you'll find!?)

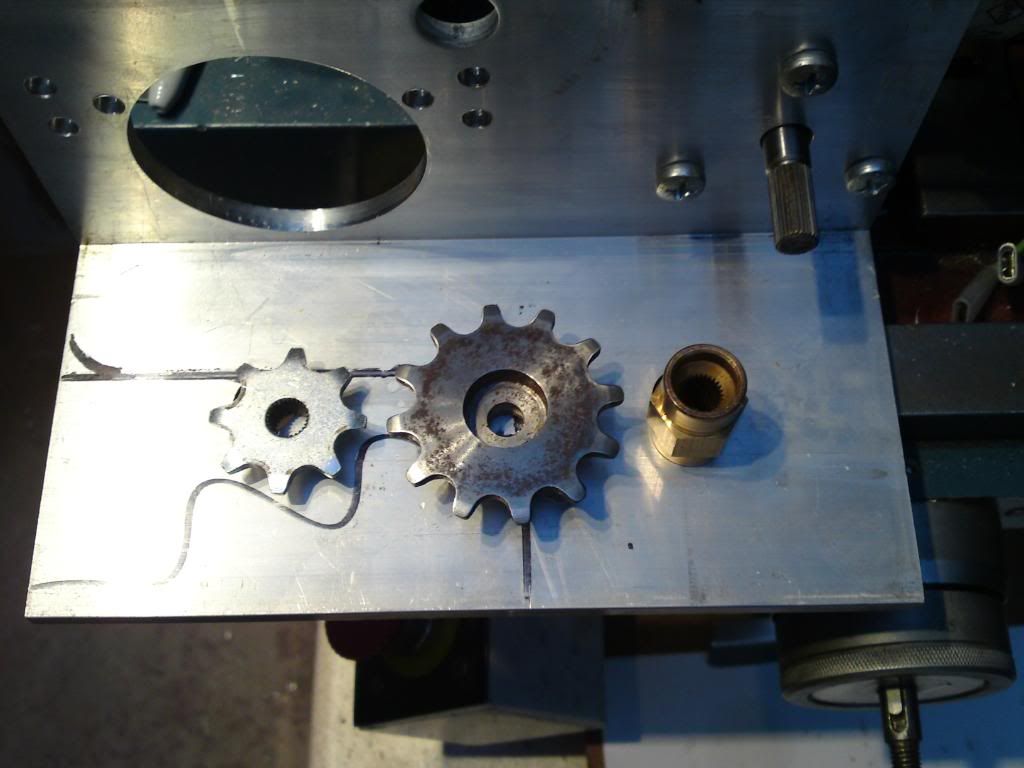

And two chain drive sprockets...

I cut the plate next to allow me to get the hand wheel on whilst I worked out the placement of the rest of the parts..

Hacksaw and drill.... Then clean up with the mill and finally a file to remove all 90degree edges.

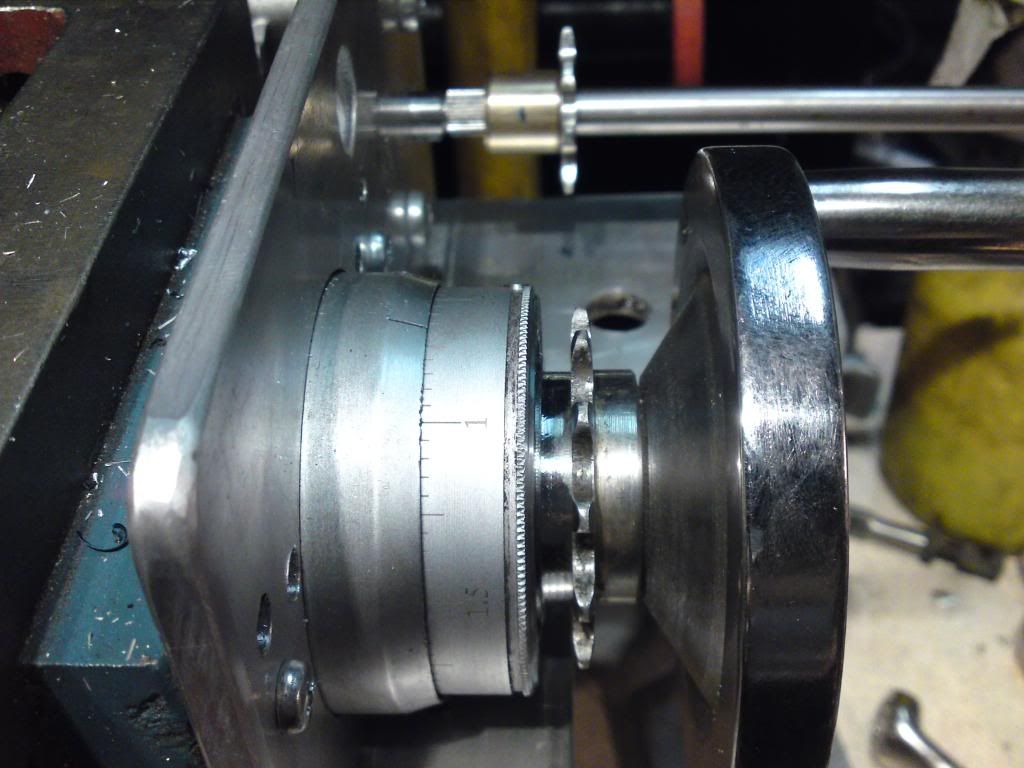

I then turned my attention to the sprockets... Drilled out the centre of the smaller one and loctited a 10mm stainless bar into it, machined the end to accept the spigot drive doofor thingy and loctited that on to the end of the sprocket.

The larger sprocket was bored out to accept the handwheel hub.

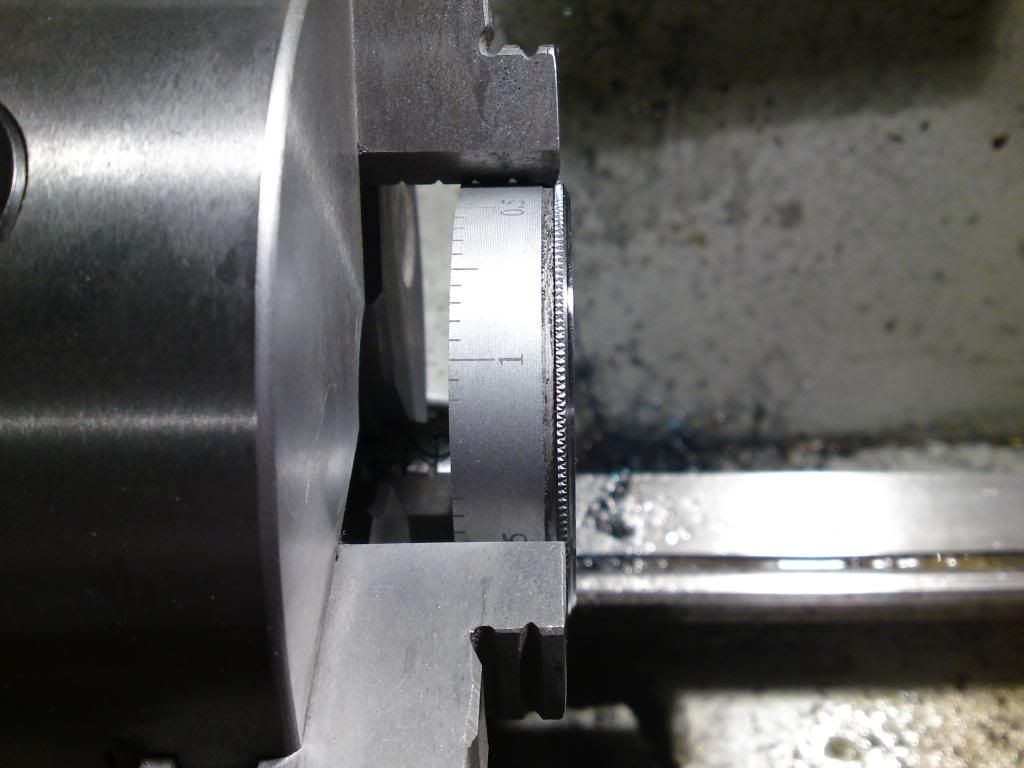

and then the dial was re-sized to allow fitting of the whole ass'y.

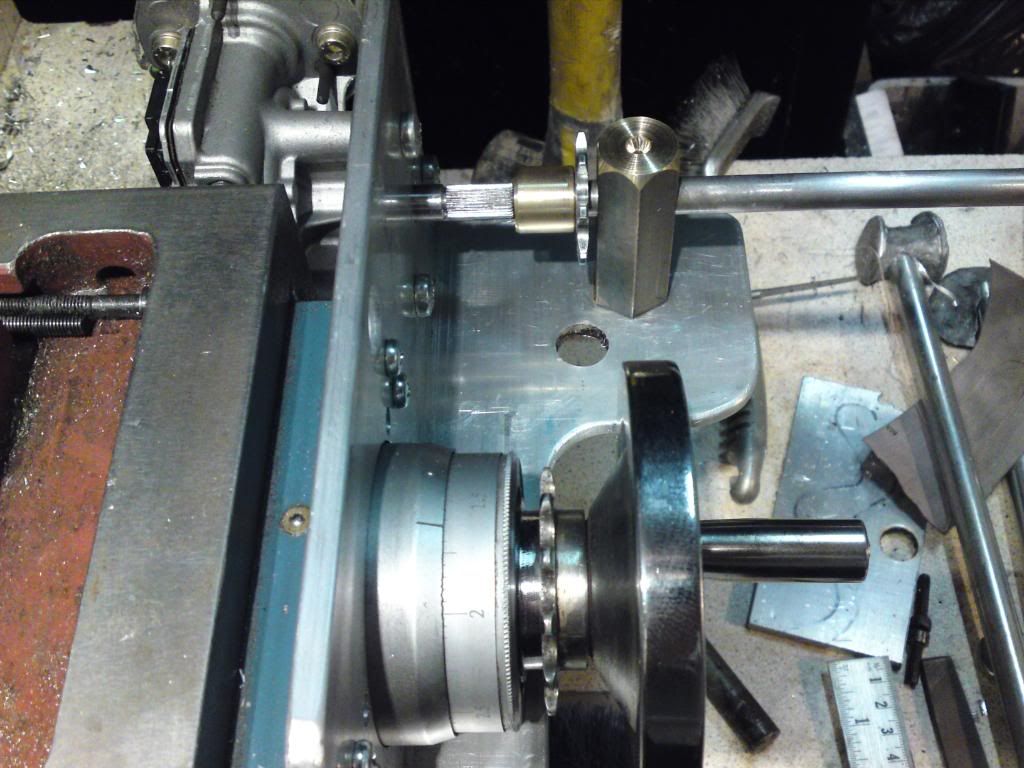

This is what we're left with...

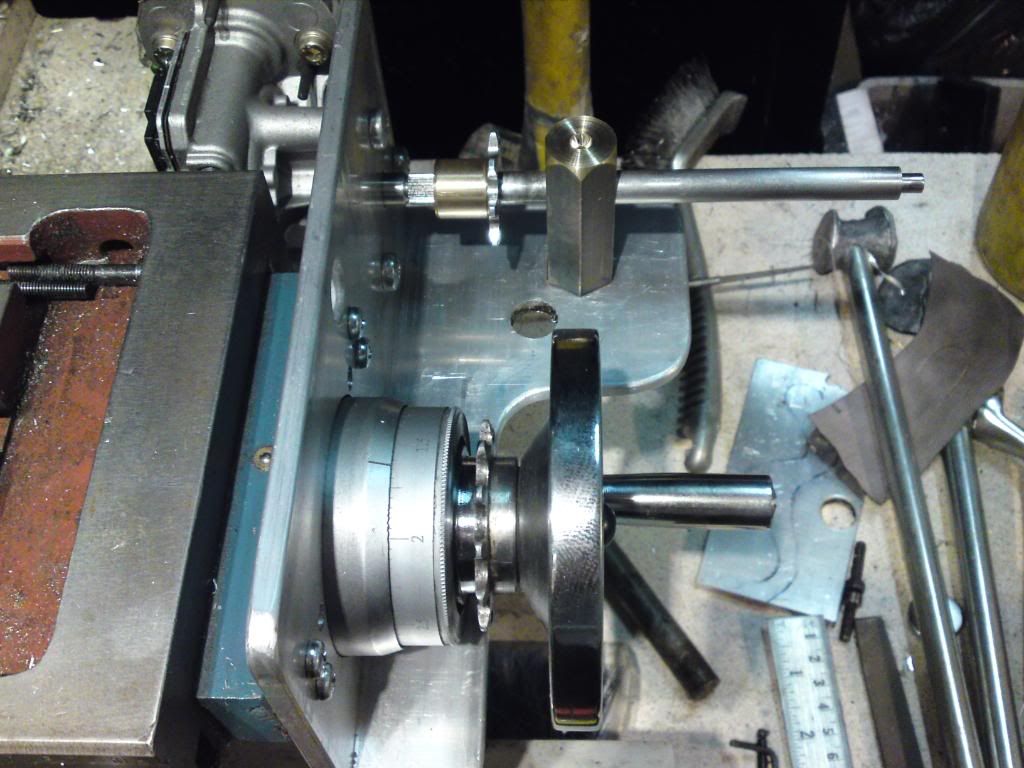

Then a bearing for the shart to allow pulling of the freely rotating shaft

And finally for last night...

Engaged...

Dis-engaged...

Bit of a monster post, but I had a lot to show

Next time, a chain and a little release mechanism for the spigot drive doofor thingy!

Ralph.