Hi all,

Between a broken down compressor

, visitors from South Africa and an extreme heat wave in Spain time in the shed was short and far between.

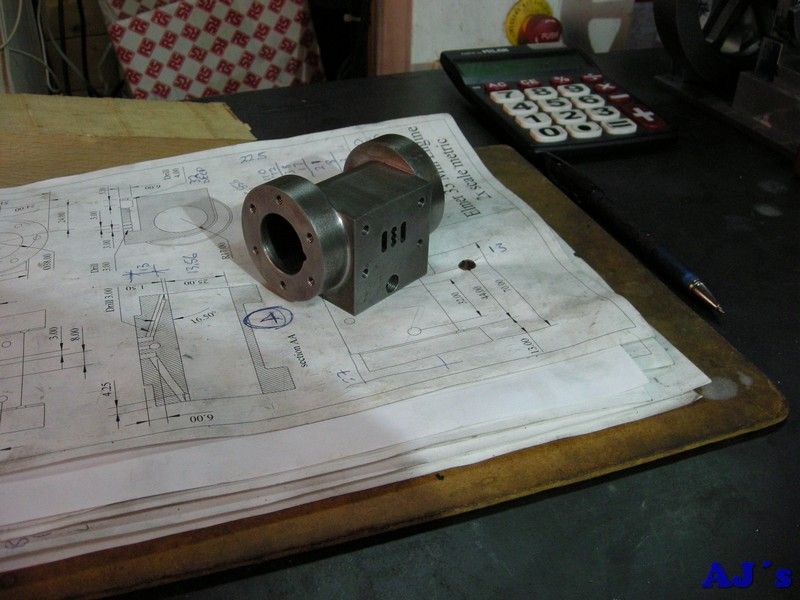

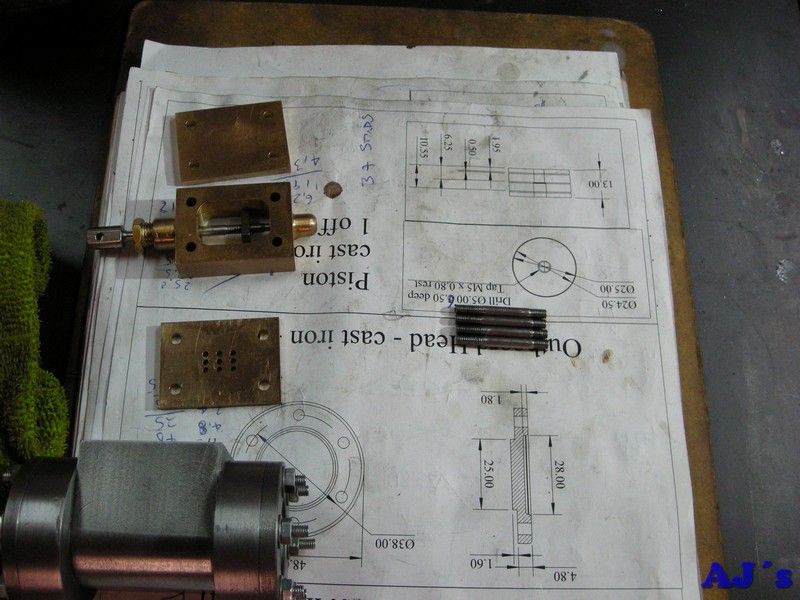

The middle sections were finally done.

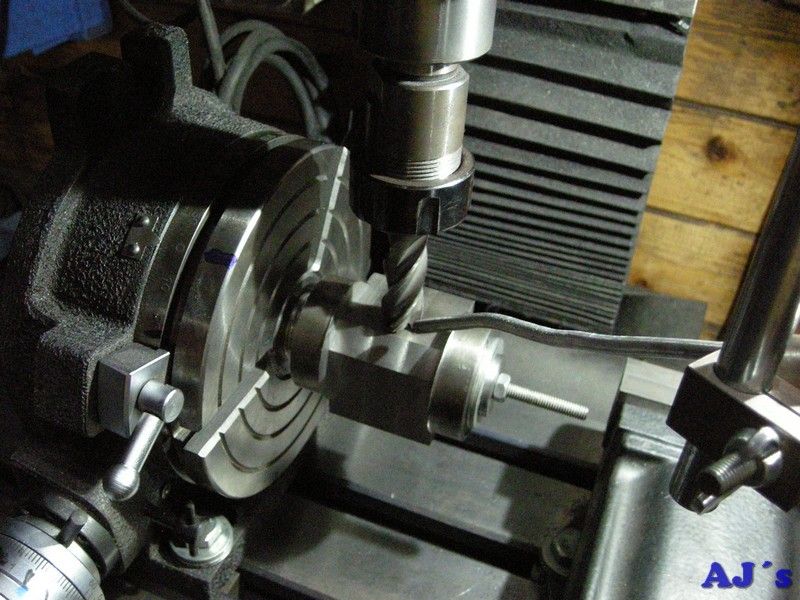

The cylinder was set up at 45 degrees to mill the comer off.

It was moved to the rotab to round over the corner.

As I do not have any slot drills or centre cutting end mills, had to do lengthwise cuts in facets every one-degree.

While on the rotab the edge on the round ends was cleaned up.

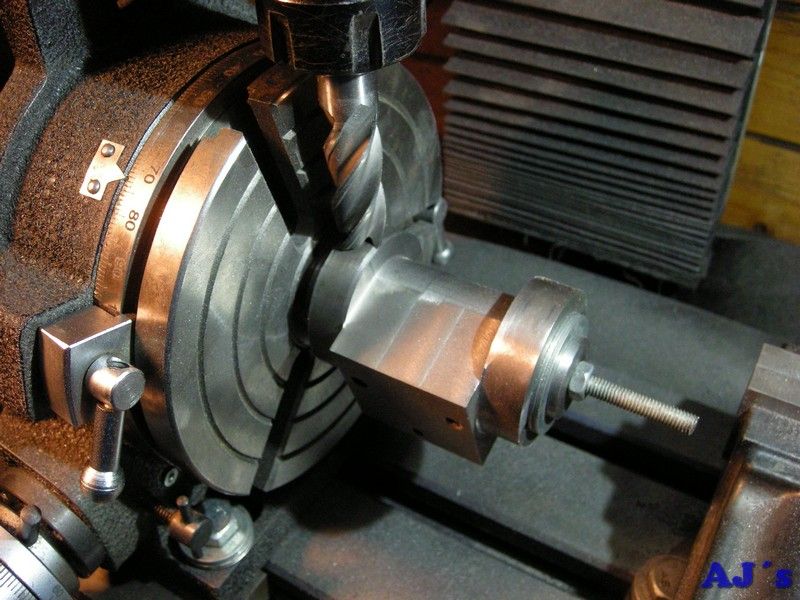

The rotab was repositioned and the mounting holes were drilled in the heads.

The heads were then used as templates to drill and tap the cylinder ends.

All done.

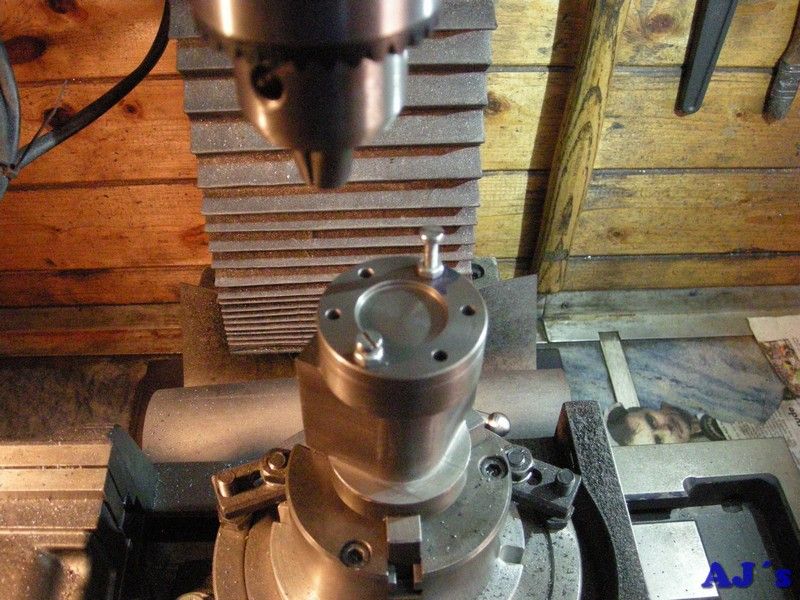

Had to re bore the cylinder as for some reason it was oval. Took the bare minimum out to get it round.

Then used a brake cylinder hone to finnish it.

The piston ended up with a bit more clearance than I would have liked, but decided to test it first before making a new one,.

Made the studs for the heads from threaded bar.

And the studs for the steam chest from bar.

The engine was assembled and I found a small error with the eccentric travel

, somehow I machined it for only half of what is needed. Had no choice but to make a new one making double sure I had the travel correct.

And we have a runner

And we have a runner, no gland packing or gaskets but it runs.

Not the best video but here she is.

Need to make some accessories and tiding up a bit.

More to follow.

Cheers

Abraham