Here is my latest project, running in the pages of

Digital Machinist magazine.

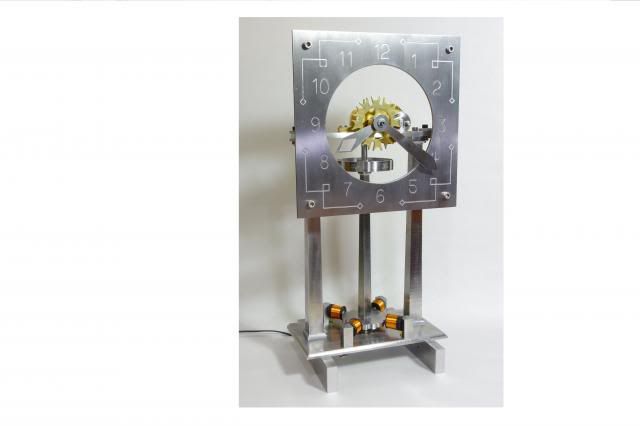

First, a closeup of the "clockworks". A 60:1 worm gear drives a horizontal shaft that carries the Geneva pinion that drives the 12:1 Geneva wheel for the hours, and a 1:1 spur gear to drive the minute hand.

I call it Geneva Hours because I used a Geneva mechanism to advance the hour hand.

Although I used CNC for many of the details, I designed the clock so that it could be built using manual machines.

The clock uses the same circuit board, with a few parts added, that I designed for the Magnetic Gear Clock.

The series will run 3-4 issues for the important details and possibly another dealing with surface treatments.

As a service to readers of Digital Machinist, I am again offering circuit boards, kits and assemblies.

Bare circuit board $15.00

Electronic parts + board $40.00

Assembled & tested $55.00

I also offer coil winding service, where readers mail me their machined bobbins and I wind the coils and add lead wires, and then mail them back. The cost is $40.00 for the four coils.

All prices are postpaid in the U.S.

I can be contacted by e-mail at wcbye@sbcglobal.net